280pcs New Design High Speed Shopping Bag Making Machine

Characteristics:

This machine is applied to manufacturing and printing the uncolored vest bags made of HDPE, LDPE roll film. It adopts PLC control, double step(servo) motor fixed length and the crystal touch screen actual display to finish the feeding, sealing, cutting, punching holes and transporting only in one process. It is of high degree of automation and good economic result.

Main Technical Variables:

|

Model |

RGHQ-500X2C |

RGHQ-400X2C |

|

Max. Bag-making width |

470mmX2 |

370mmX2 |

|

Max.Bag-making length |

650mm |

650mm |

|

Bag-making thickness |

0.015-0.035mm |

0.015-0.035mm |

|

Bag-making speed |

280pcs/minX2 |

280pcs/minX2 |

|

Air pressure |

7kg/cm2 |

7kg/cm2 |

|

Total Power |

12kw |

15kw |

|

Weight of machine |

2500kg |

2000kg |

|

Overall dimensions |

6.5*1.5*1.6m |

6.5*1.6*1.6m |

Usage: it can make shopping bag for supermarket

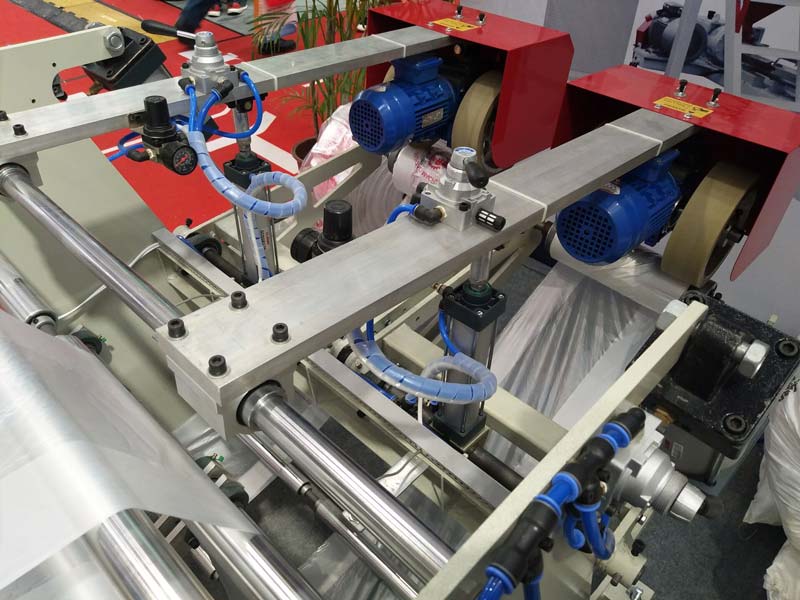

Machine Details: Unwinding Parts---Automatic tension control

1,Air Cylinder to Load the film rolls automatically.

2, AC Motor Tension Controlling System

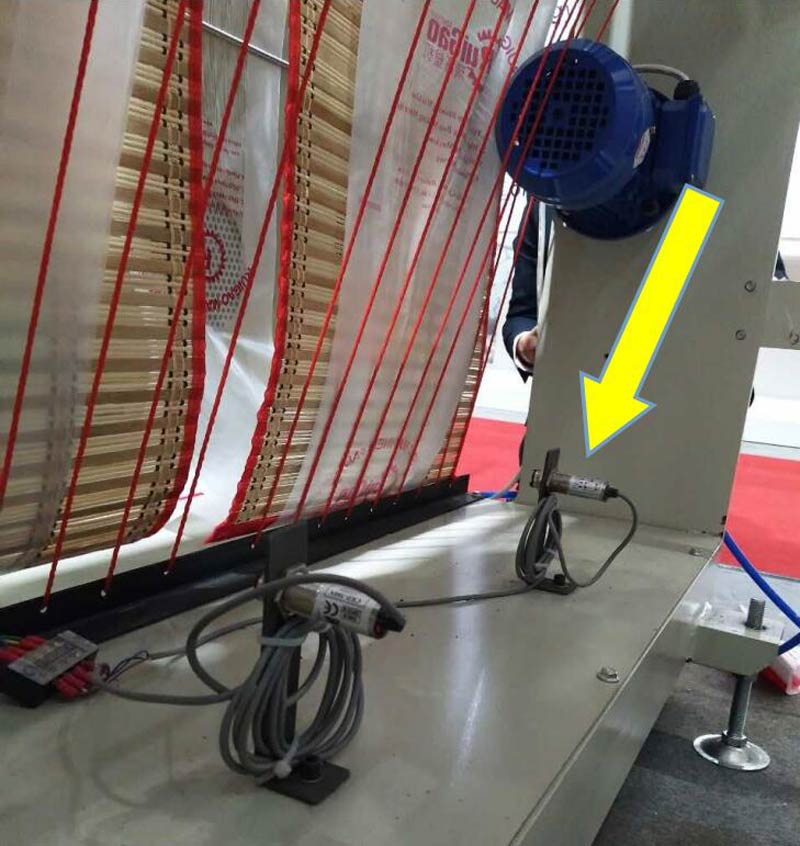

Machine Details: Dancing Roller to control tension

Machine Details: Automatic Stop machine when the film roll is finished

Machine Details: Air controlling system for unwinder.

1, The blower to keep film feeding more stable.

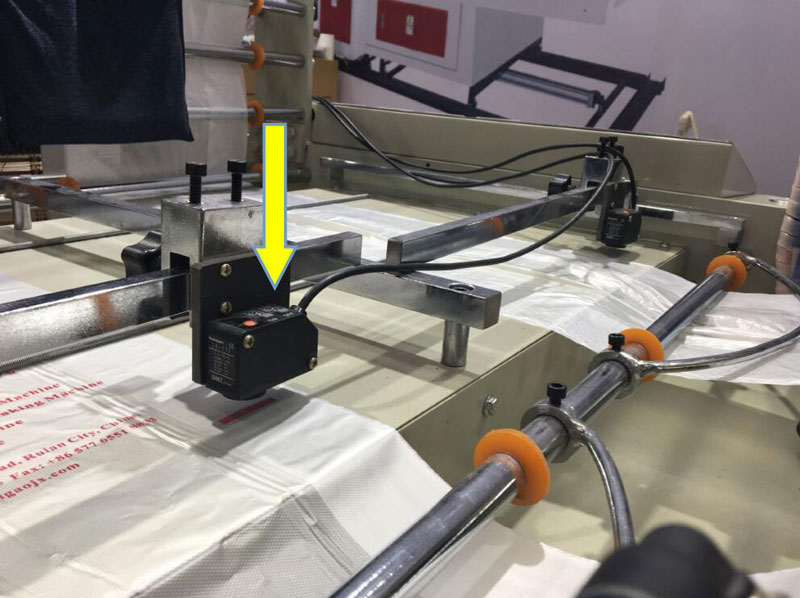

Machine Details: Photo Sensor to control the unwinder rolls.

Machine Details: Photocell Sensor---Panasonic

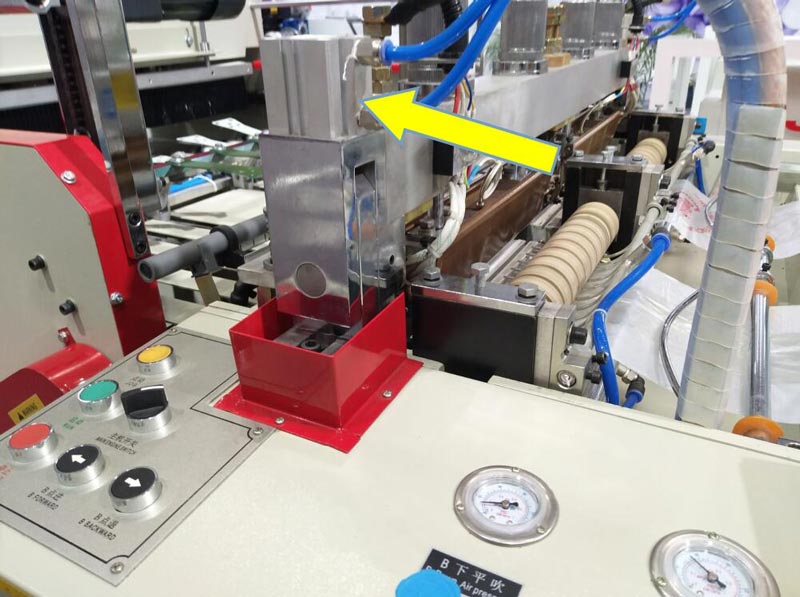

2, Sealing Knife holder controlled by Air, Easily to change knife.

3 Sealing knife with high quality cooper

4, Movable Stacking Parts.--The batch bag will not be seal together

5, Punching Parts:---Clutch hand

6 Air Cylinder---3 Ton pressure

7, Punching Conveyor

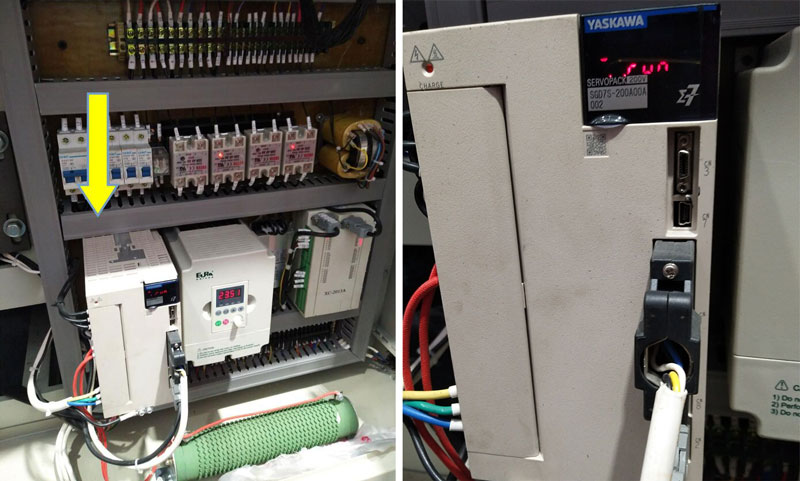

7, Yaskawa servo motor & Eura Inveter

8, Touch Screen with PLC

9, Air Controlly system.

> What are plastic bags made of?

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produ...

> What is the market prospect of Bag Making Machine?

The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to ma...

> How to Choose a Good Bag Making Machine?

A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and s...

> What are the similarities between fully automatic bag making machines and semi-automatic bag making machines

The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manual...

> What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These mac...

> What is the Manufacturing Process of plastic bag

Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled ...

English

English Français

Français Español

Español