English

English

English

English

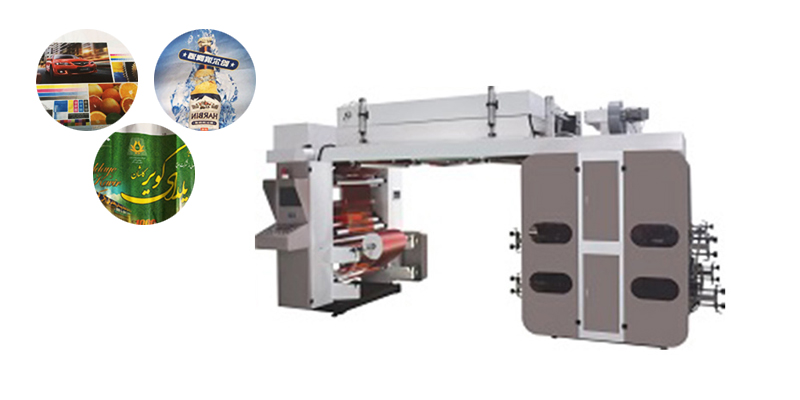

For our printing machine,we have different type printing machine. We have stack type and CI type. Different type the printing speed and price are different.

● For the stack type printing machine, we use helical gear and Siemens brand main motor. The printing speed can run 70m/min. This machine is very popular for printing plastic shopping bag.

● Another stack type printing machine, we use timing belt and Siemens brand main motor. The printing speed can run 80-100m/min. The printing precision is more accurate. And low noise of running printing machine.

● For CI printing machine, there is central drum, So there is no jogging of printing color registration. And printing speed can run to 150-180m/min. This CI printing machine is suitable for high quality food packing bag printing.

Tplast Printing machine is high quality and Competitive Price. We use Helical gear for whole machine and Siemens motor control. The main machine speed running very stable and the printing precision is also very perfect. The printing machine can print on paper, plastic film, non woven fabrics ect. And it is easily to change the printing plate.

The printing machine is suitable for printing plastic film and paper both. First we put the film roll on unwinder, which has the automatic tension control system and EPC. The film tension will influence the printing quality. So we need install the automatic tension system. The film will cross the printing parts, which contain the Ink roller, Anilox roller and plate roller.

Different printing pictures, we need use relative Anilox roller which has the steel anilox roller and Ceramic Anilox roller. And there is Doctor blade to choose. The doctor blade will make the ink more even, and printing quality will be more better. We have two type blade, one is single face doctor blade, another is Closed chamber doctor blade. The closed chamber doctor blade is suitable for high speed type printing machine.

After printing, the film will cross the drying system. The printing machine drying system is big oven and closed type. It can dry the ink faster then the open type and normal type dryer. Finally the rewinder will rewind the printed film roll. The rewinder is also with automatic tension control and air shaft, which is easily for worker operation.

Each year we improve our machine quality. We will follow our customer feedback and our industry advanced company technology. We will not stop the quality improvement.

After sale service is important for our customer. It is for whole life of machines. If customer feedback any problems we will help him to slove it and rethink our machine design.

We have very professional research and sale team. We will try our best to improve their income and happiness both. Beacuse if they feel happy, our customer will be happy also.

High speed Printing Machine factory & supplier provides what is Printing Machine, machine price, working principle,and other information.

The ideal machine directly impacts your production efficiency, product quality, and long-term profitability.

Read More >In the landscape of modern industrial manufacturing, efficiency is the cornerstone of profitability and market competitiveness.

Read More >When you plan to launch or scale up a plastic bag manufacturing business, picking the right equipment plays a critical role. A machine designed specifically for producing plastic bag films often sparks questions: What sets it apart from other film-producing devices? What actual advantages can it off...

Read More >In the packaging industry, machines that turn plastic films into usable bags play a key role. Many packaging professionals or newcomers wonder about their basic working process—this article breaks it down clearly to show how raw materials become finished bags.

Read More >Plastic packages are omnipresent in daily life, from food bags to product wrappers. Printing on these packages – for brand logos, usage instructions or safety info – is essential. But why can’t regular printers take on this task? The answer is that the unique demands of producing plastic materials a...

Read More >A well-running Bag Making Machine is key to steady, efficient packaging production. After long-term use, dust, component wear, or incorrect operation can reduce its performance and even cause unexpected breakdowns. For daily users, proper maintenance is essential to extend its service life and avoid...

Read More >GET A QUOTE