English

English

English

English

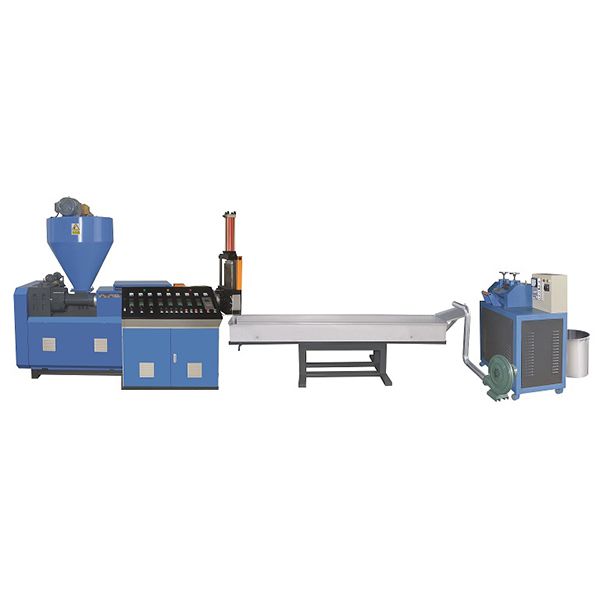

Tplast Plastic Recycling Machine can recycle waste Plastic Like PE, PP and Biodegradable materials. Which is very friendly for environment. The recycling machine is used with hard surface gearbox. It is low noise and stronger pressure. The screw is Bimetal materials, so machine can run longer life. The recycling machine die head is hydraulic screen changer. And cutting knife is hobbing cutter with alloy steel. The whole machine quality is very stronger and perfect output.

Our plastic recycling machine is suitable for PE and PP materials. It can recycle the waste plastic to make new materials.

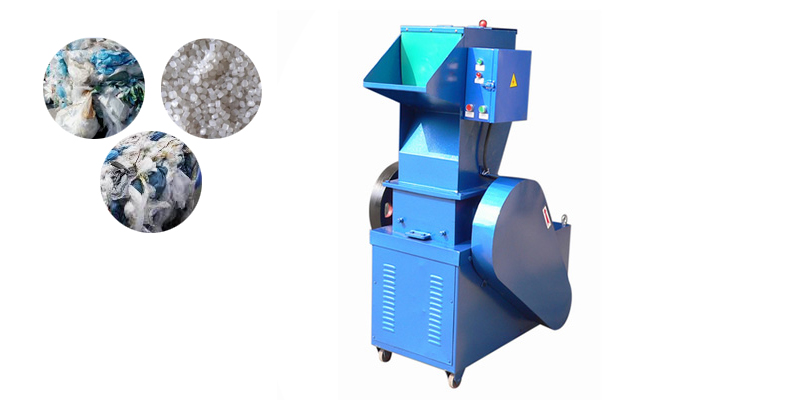

Waste Film

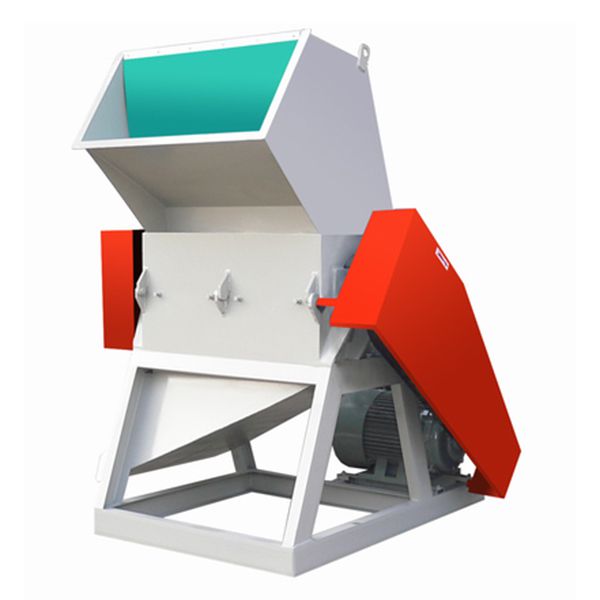

Waste Film Grinding Machine

Grinding Machine Recycling Machine

Recycling Machine Final Pellet

Final PelletThe plastic recycling machine have one loader, we put the crushing plastic materials into the loader. We have the forced feeder system which is suitable for plastic film. If we recycle the hard plastic materials, we can use normal loader. And the screw will feed the crushing plastic into the barrel. And there is ceramic heating for barrel, it will plastic the materials. And there is hydraulic screen changer which can prevent the dirty materials crossing the die head. So the final material will be very clean.

And there is stainless water tank, we put the running water to cool the final materials, so it will be more round. There is drying blower connected with water tank. It can dry the materials very good.

The last step is the cutting plastic pellets. The cutting machine hobbing cutting knife is alloy steel, which is very hard and stronger. And the speed is adjusted by inverter, So it can cut the materials more.

√ Plastic recycling machine can recycle PE and PP materials. It can recycle the waste film and plastics. So it is very friendly to the environment.

√ Our plastic recycling machine use bimetal materials for screw, So it is no problems for the waste plastics, it means screw and barrel can run longer time.

√ And this recycling machine have the hydraulic screen changer, which can clean the materials. We just to change the filter and save time.and worker is easily to operate also.

√ For the cutting parts, we use alloy steel, it is very stronger and hard. So recycling machine can run very longer time.

TPLAST is a plastic machinery company with years of experience in the production of plastic bag machines. As a specialist manufacturer of plastic bag making machines, we have a broad range of bag making machinery, such as flat bag making machine, bag on roll making machine and specialty bag making machine, to suit various plastic bag production needs.

Printed and non-printed PE, PP film, multi-layered film, shrink film, stretch film, PE and EPE foam. Thermoformed PS, PP. Soft irrigation pipe. Pre-shredded regrind. Washed and dried film flakes from washing line.

PE/PP Film Roll

Waste Bags

Garbage Bag

Shrink Film

Bubble Film

Film Sheet

Each year we improve our machine quality. We will follow our customer feedback and our industry advanced company technology. We will not stop the quality improvement.

After sale service is important for our customer. It is for whole life of machines. If customer feedback any problems we will help him to slove it and rethink our machine design.

We have very professional research and sale team. We will try our best to improve their income and happiness both. Beacuse if they feel happy, our customer will be happy also.

Plastic Recycling Machine factory & supplier provides what machines are used to recycle plastic, process, how to make a plastic recycling machine and how work, types, prices, and other information.

The ideal machine directly impacts your production efficiency, product quality, and long-term profitability.

Read More >In the landscape of modern industrial manufacturing, efficiency is the cornerstone of profitability and market competitiveness.

Read More >When you plan to launch or scale up a plastic bag manufacturing business, picking the right equipment plays a critical role. A machine designed specifically for producing plastic bag films often sparks questions: What sets it apart from other film-producing devices? What actual advantages can it off...

Read More >In the packaging industry, machines that turn plastic films into usable bags play a key role. Many packaging professionals or newcomers wonder about their basic working process—this article breaks it down clearly to show how raw materials become finished bags.

Read More >Plastic packages are omnipresent in daily life, from food bags to product wrappers. Printing on these packages – for brand logos, usage instructions or safety info – is essential. But why can’t regular printers take on this task? The answer is that the unique demands of producing plastic materials a...

Read More >A well-running Bag Making Machine is key to steady, efficient packaging production. After long-term use, dust, component wear, or incorrect operation can reduce its performance and even cause unexpected breakdowns. For daily users, proper maintenance is essential to extend its service life and avoid...

Read More >GET A QUOTE