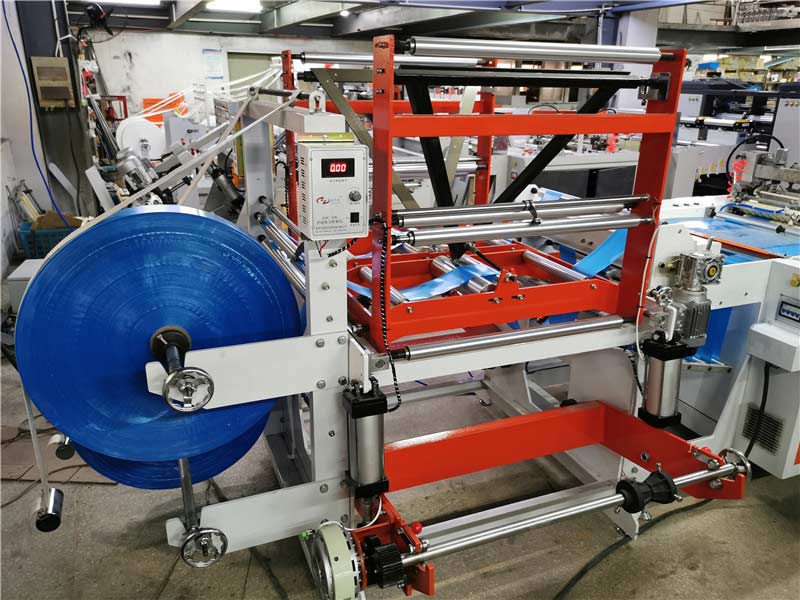

Fully Automatic Roll Bag Making Machine

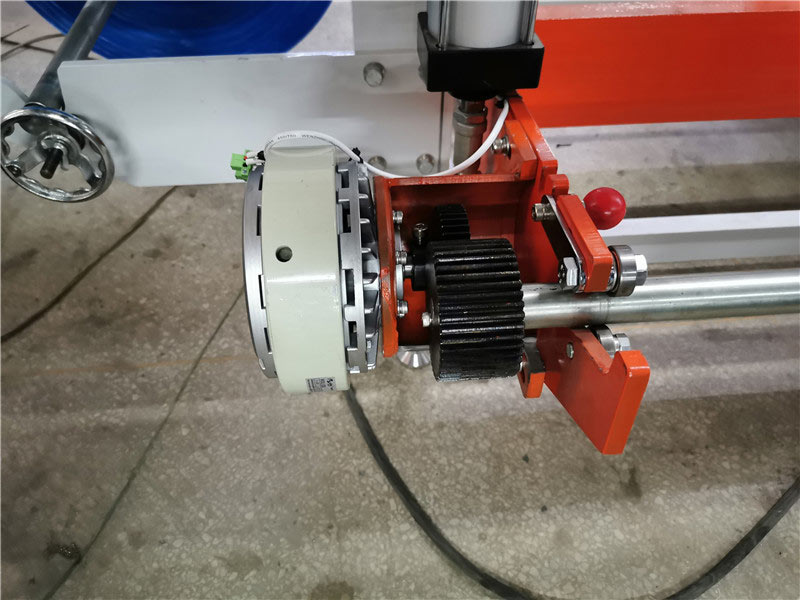

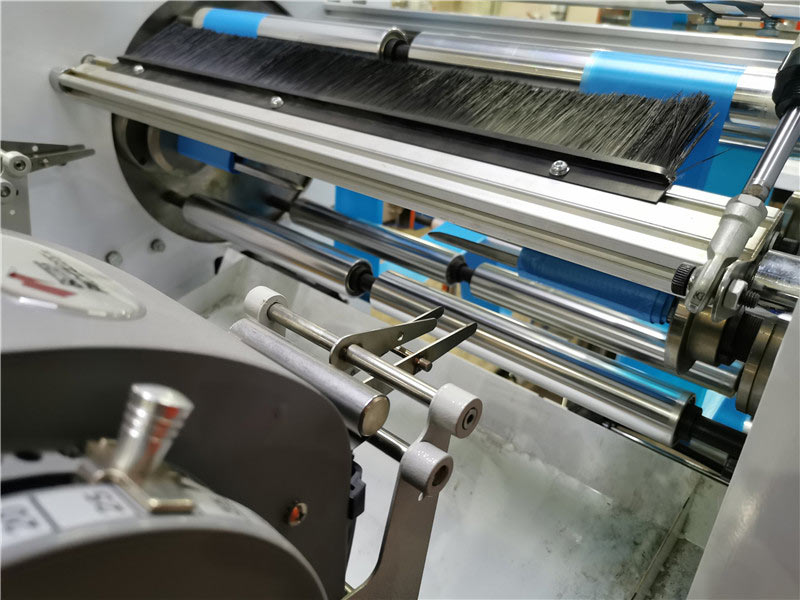

The automatic roll bag making machine is controlled by computer, and the stepping (servo) fixed-length system makes the sealing and cutting size error small. The electric eye tracking device makes the pattern position of the printing bag accurate. The length of the bag can be adjusted by computer numerical control.

Main Parameter

|

Type |

TPGB-300X2 |

|

Unwinder roll width(two lines) |

180-500mm |

|

Final roll bag width(two lines) |

80-250mm |

|

Bag length |

450-1200mm |

|

Bag thickness |

0.01-0.05mm |

|

Bag speed |

80-100m/min*2 lines |

|

Air pressure |

5.5HP |

|

Total power |

12.5KW |

|

Weight |

2400KG |

|

Size |

5000x2100x1500mm |

> What are plastic bags made of?

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produ...

> What is the market prospect of Bag Making Machine?

The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to ma...

> How to Choose a Good Bag Making Machine?

A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and s...

> What are the similarities between fully automatic bag making machines and semi-automatic bag making machines

The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manual...

> What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These mac...

> What is the Manufacturing Process of plastic bag

Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled ...

English

English Français

Français Español

Español