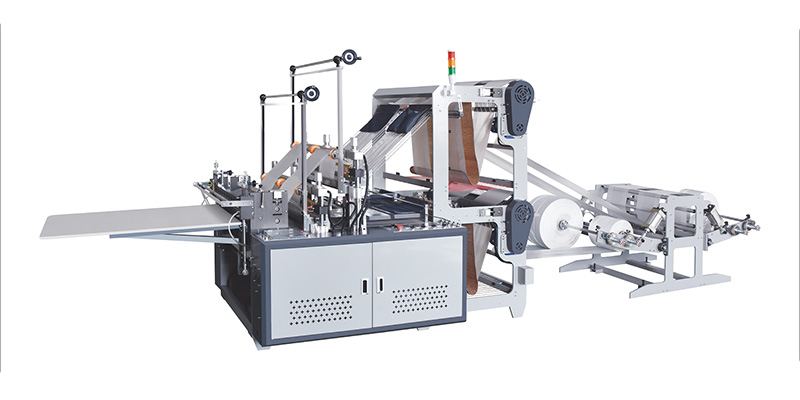

New Design 4 lines Biodegradable bag-making machine

Application

It is used for producing Biodegradable vest bags and flat-opening bags. The main motor adopts Taiwan frequency conversion motor to save more electricity and regulate speed more freely. The unwinder is Taiwan design, Same speed as main machine.And All electric parts is Famous brand. Longer life also. It is fully automatically, save worker and protect environment.

Main Technical Variables

|

Model |

TP-DLA800 |

TP-DLA1000 |

TP-DLA1200 |

|

width of sealing &cutting(mm) |

750*2 360*4 |

950*2 460*4 |

1150*2 560*4 |

|

length of sealing & cutting(mm) |

1500 |

1500 |

1500 |

|

speed of bag-making (pc/min) |

280-560 |

280-560 |

280-560 |

|

Power of motor(kw) |

1.5 |

1.5 |

2.2 |

|

Weight(kg) |

1500 |

1600 |

1700 |

|

Outline dimension |

4.8*1.4*1.9 |

4.8*1.6*1.9 |

4.8*1.8*1.9 |

Shopping bag for supermarket

Garbage bag for Family or Hotel

Unwinder

Auto loading system,

It will save the worker power consumption

And easily to operate.

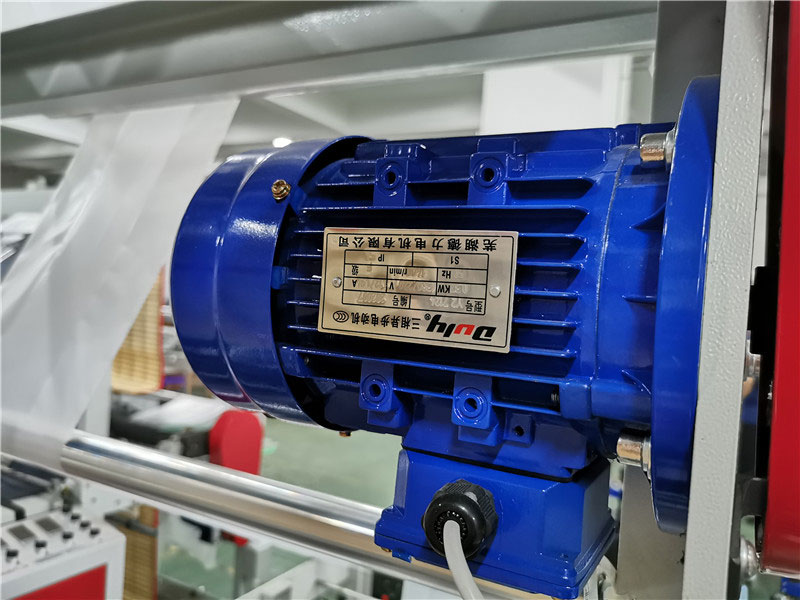

Unwinder Motor

1, AC motor Control, Not easily burnt

2, Delta inverter control speed, Taiwan brand high Quality

Unwinder Design

1, Air control the rubber roller, Easily for worker to operate

2, 12mm steel plate as body, it will be very stable for running machine

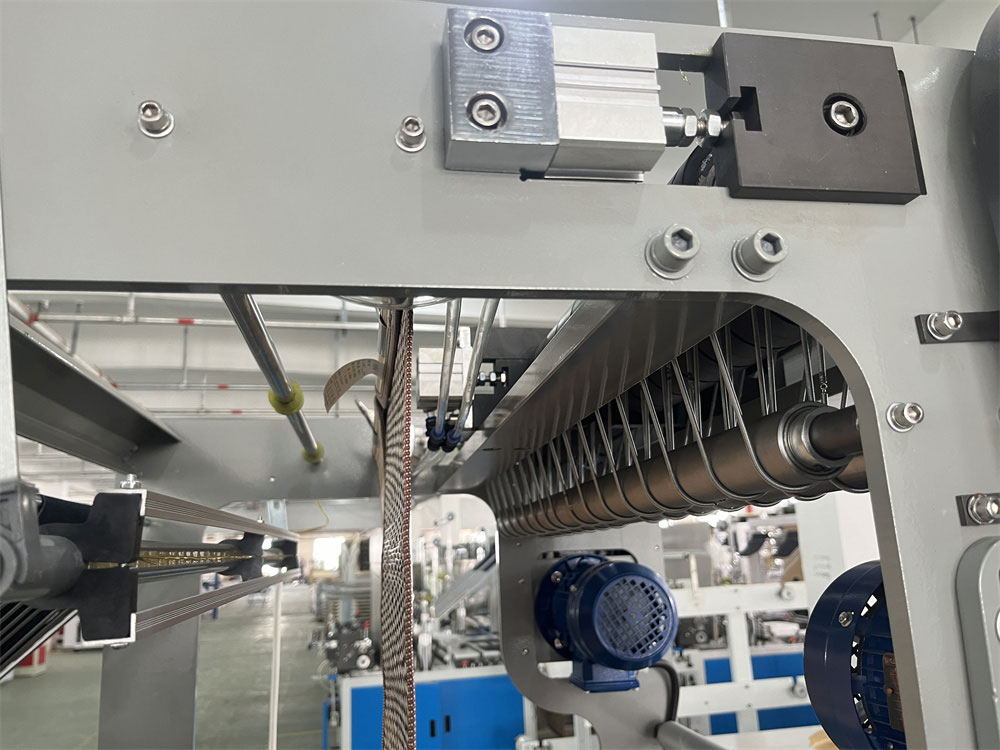

Rubber Roller Design

1, it can do 4 lines small size bag with separate rubber roller

2 it can do 2 lines big size bag with connection rubber roller

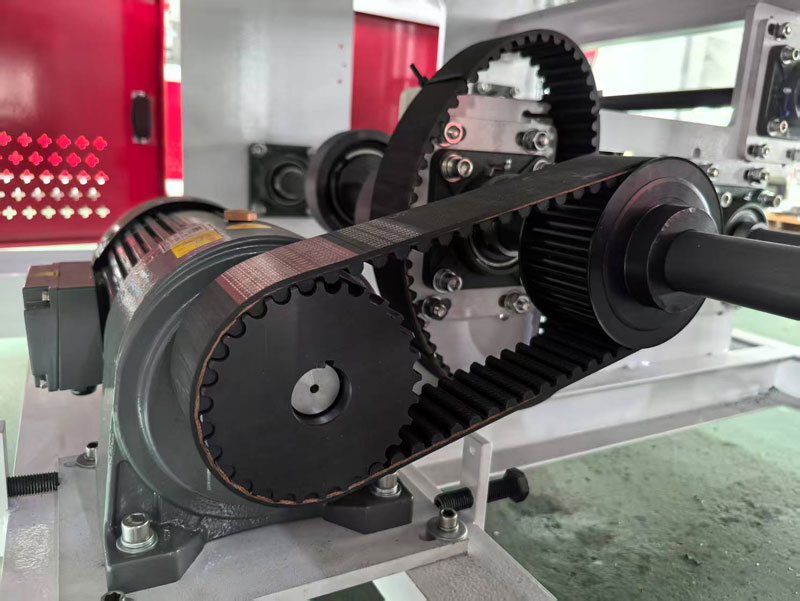

Transfer -New Design

We use the Timing belt instead of chain.

So it is no any noise from machine inside

And we keep extra belt with machine for future.

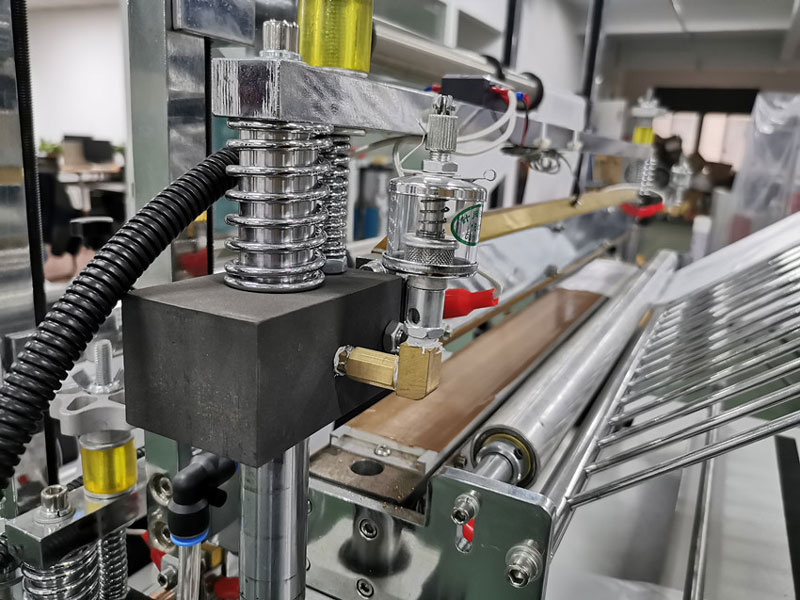

Cam for Sealing knife -New Design

This design can improve the speed of machine from 120pcs/min to 140pcs/min.

It will help us to improve output of product.

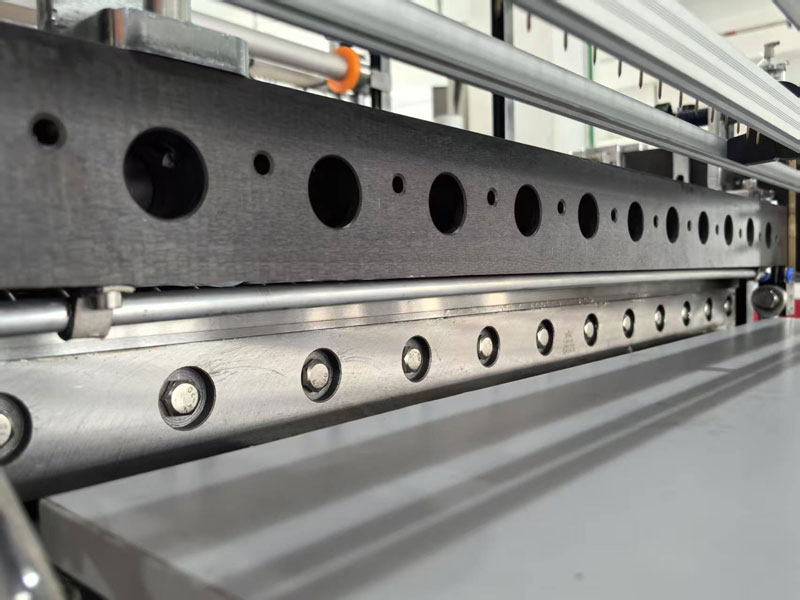

Stronger Sealing bar

We use 50*50mm Aluminum Bar to hold the sealing knife. So it will be very stronger than before. And the sealing lines will be perfect.

Oil Cup ----Good Lubrication design

We put oil in whole cup, and it will lubricate the sealing shaft automatically. The machine will running longer and low noise

Cutting Knife Design

1 Alloy Steel materials for knife, longer knife.

2, Spring Type design, it will reduce the noise of cutting, make the knife longer

Electric Control

1, Delta Inverter control for whole machine motor

2 Fotek relay and Schneider electric Parts

It is very famous parts, so machine will be no headache

> What are plastic bags made of?

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produ...

> What is the market prospect of Bag Making Machine?

The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to ma...

> How to Choose a Good Bag Making Machine?

A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and s...

> What are the similarities between fully automatic bag making machines and semi-automatic bag making machines

The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manual...

> What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These mac...

> What is the Manufacturing Process of plastic bag

Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled ...

English

English Français

Français Español

Español