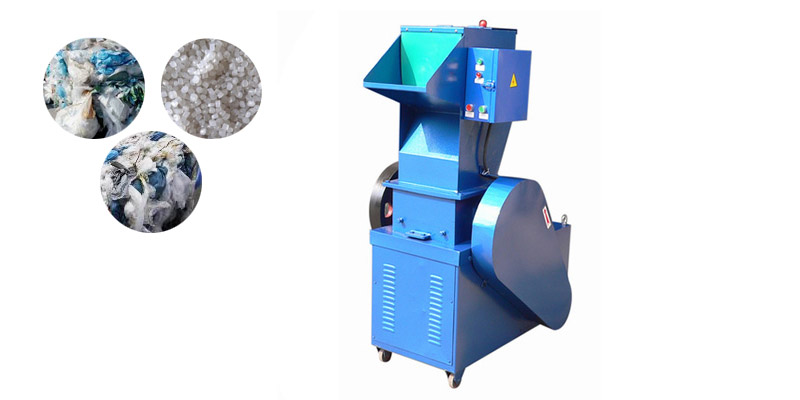

A Beginner's Guide to Running a Plastic Recycling Machine

For beginners, operating a Plastic Recycling Machine can feel intimidating—you may worry about equipment damage or inconsistent output. But with simple, practical steps, you can easily process common plastic waste (like polyethylene scraps) into reusable material. This guide breaks down core operations without complex jargon, focusing on efficiency and safety.

Prepare the Right Plastic Waste

Sort by compatibility: Stick to plastics the machine handles, such as polyethylene (PE, used in grocery bags or plastic wraps) and polypropylene (PP, found in yogurt cups or bottle caps). Check the recycling symbol on items to avoid mismatched waste.

Remove contaminants: Pick out non-plastics (metal staples, paper stickers, glass bits) — these can scratch internal parts or ruin the final product. Even small debris like food crumbs should be wiped off.

Clean and dry thoroughly: Use a mild detergent to remove oil or food residue from scraps, then let them air-dry completely. Moisture causes clumping in recycled plastic, while dirt leaves unsightly spots.

This prep ensures the machine runs smoothly and the recycled material is fit for reuse (e.g., making small plastic parts or new bags).

Follow Basic Safety Protocols

Wear protective gear: Heat-resistant gloves prevent burns from warm machine parts (critical when handling fresh scraps). Safety goggles block tiny plastic fragments that may fly during processing. Avoid loose clothing or long hair—tie hair back and roll up sleeves to stop them from getting caught.

Learn emergency controls first: Locate the bright red emergency stop button (usually on the front panel) and practice pressing it once. This lets you react fast to jams or strange noises (e.g., grinding) without panic.

Never touch moving parts: If you spot a jam, turn the machine off fully first. Use a plastic tool (not your hands) to clear blockages—hands near moving components risk serious injury.

Do Routine Pre-Operation Checks

Inspect external parts: Check for loose wires (fix gently or ask a pro), cracks in the housing (a sign of internal damage), and blocked feeding chutes (use a small brush to clear debris).

Ensure stable power: Plug into a dedicated outlet—avoid overlong extension cords (they reduce power flow). Use a surge protector if your area has frequent power flickers to prevent unexpected shutdowns.

Check lubrication (if needed): Refer to the user guide to find lubrication points (e.g., gears). Add a small amount of recommended oil—too little causes friction, which wears parts down quickly.

A 5-minute check avoids costly breakdowns later.

Monitor the Output for Quality

Check consistency: Recycled plastic (usually pellets or flakes) should be uniform in color (matching input scraps) and size. If you see discolored chunks or uneven pieces, stop the machine—you may have missed a contaminant.

Watch for warning signs: Strange odors (like burning plastic) mean overheating—turn it off and let it cool. Slow output often signals a clogged chute; clear it once the machine is off.

Avoid overloading: Add scraps in small batches. Dumping too much at once clogs the machine and strains its motor, shortening its lifespan.

Conclusion

Running a Plastic Recycling Machine as a beginner is far from impossible—focus on prepping waste, staying safe, doing quick checks, and monitoring output. These steps turn plastic waste into valuable material while protecting you and the equipment.

If you’re ready to start your recycling journey and need a reliable Plastic Recycling Machine, ebrowse our product range. Our equipment aligns with these simple operations, helping you build a sustainable plastic reuse routine effortlessly.

English

English Français

Français Español

Español