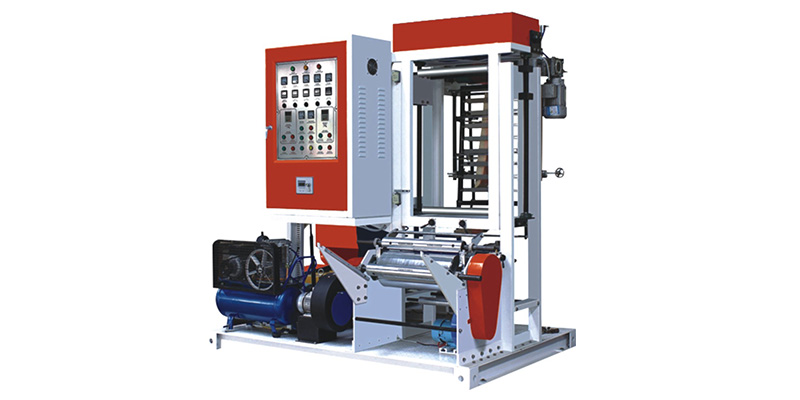

Mini Film Blowing Machine

Mini Film Blowing Machine Features

(1) Good hardness and corrosion resistance

Mini blown film machine is extruder, barrel, and screw are all made of high-quality alloy steel, which has been nitrided and precision processed.

(2) The plasticizing quality is good, which is conducive to increasing production capacity.

The main motor meets CE standards, the screw and barrel are made of 38CrMoAlA, the gearbox has a lifespan of more than 10 years, and the 130w blower fan cools the screw faster.

Mini Film Blowing Machine can do hdpe, ldpe and llpde. This machine is designed with the whole plate for the bottom, so the size of smaller, and no need to install machines just to connect the power and air.

Mini Film Blowing Machine application scope:

production of food, clothing, garbage bags, vest bags, and other packaging bags, suitable for LDPE, HDPE, LLDPE, and other plastic films.

Mini Blown Film Machine Parameter

|

Model |

TP45 |

|

Diameter of screw |

Φ45 |

|

Max width of Film |

100-500mm |

|

Single-face Thickness of film |

0.008-0.10mm |

|

Output |

30kg/h |

|

L/D |

28:1 |

|

Power of main motor |

11kw |

|

Power of Traction main motor |

1.5kw |

|

Total Power |

20kw |

|

Outline diameter |

2300 x 2000 x 2300mm |

|

weight |

1500kg |

Mini Blown Film Machine Main Parts Parameter and pictures:

Whole Machine

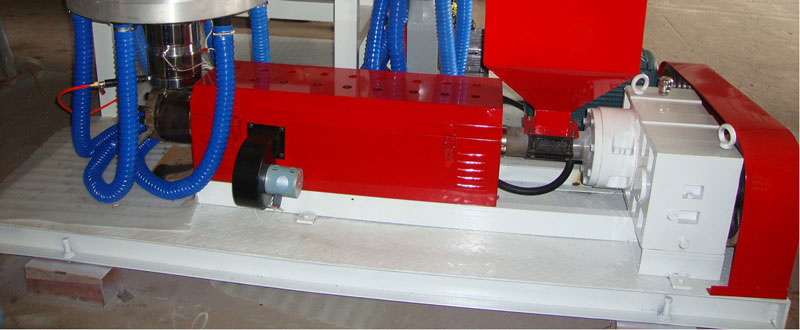

Screw:

1.Material of screw and barrel: 38CrMoAlA

2.Material Element Analysis:

C: 0.35~0.42 Si: 0.20~0.45 Mn: 0.30~0.60 S: ≤0.035 P: ≤0.035

Cr:1.35~1.65 Al: 0.70~1.10 Ni: ≤0.030 Cu: ≤0.030 Mo:0.15~0.25

3.Hardness of tempering: HB260-290

4.Depth of nitriding: 0.4-0.7mm

5.Hardness of surface: HV900-1050

6.Roughnessof surface:Ra0.32

7.Linearity of screw: 0.015mm/m

Main motor:

1, It is Chaoyue brand Main motor, CE standards

2, Speed is 1400rpm, 6pole type, bigger power.

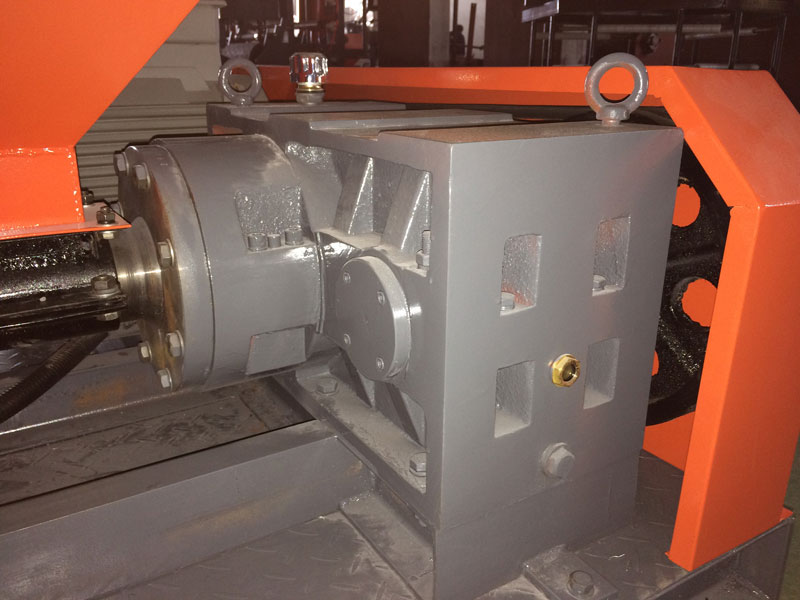

Gearbox:

1, It is Hard gearbox, more 10 years life

2, Lubrication oil with oil mark, which make bearing smoothly

Heater:

1, It is Stainless heater,which life is more 5 years

2, Thermal couple is E type, which is touch the temperature of barrel

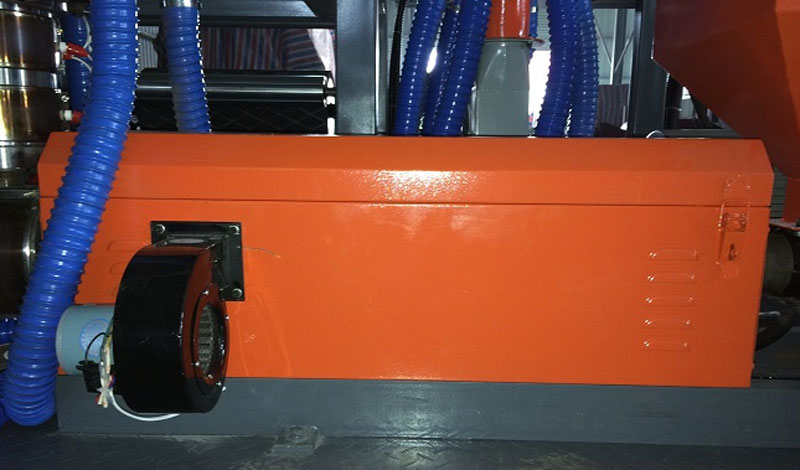

Cover:

1, 1.2mm thickness Steel Cover.

2, 130w blowing fan, to cool the screw faster.

Fixed Die head:

1, Machine with HDPE and LDPE die head to change.

2, Die head with Polishing, Nitrigend. It is very smoothly inside.

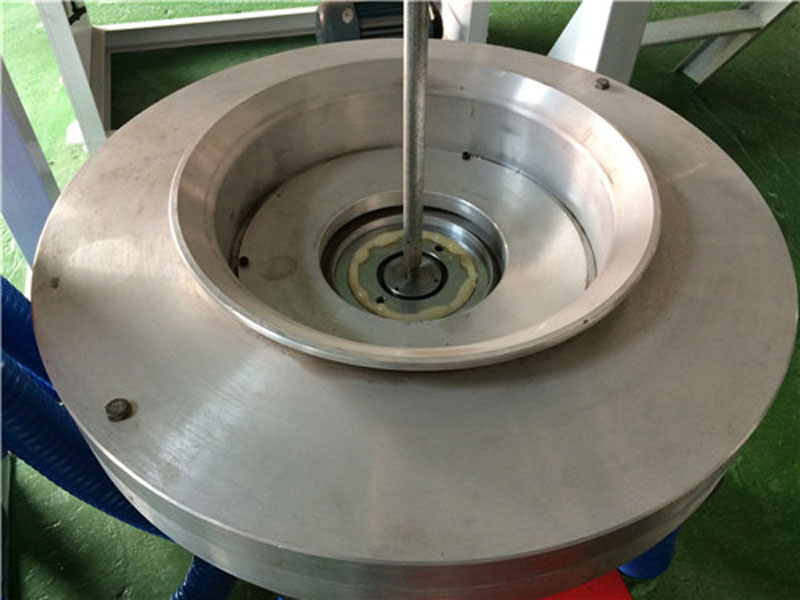

Air ring:

1 Single Lip air ring, Aluminum materials. 6 air inlet.

2, High speed blower to cool the film, cooling fast.

Screen change:

1, T Type, we need change the filter by Manual. No Leakage

2, Filter size: 50LPI, stainless or steel.

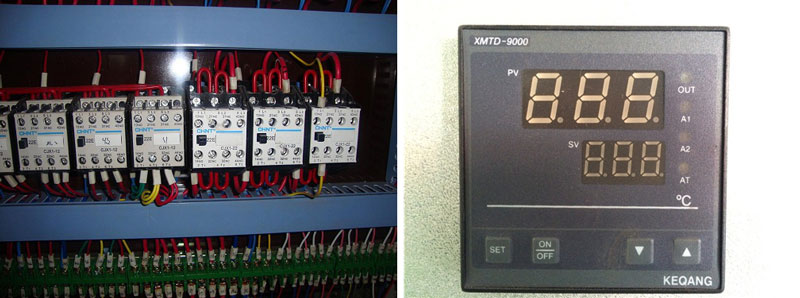

Electric parts:

1, KEQANG Temperature controller, More 10 year life.

2, CHINT brand Contact, best Quality in China.

Eletric controller box and inverter:

1,Shenou Brand Inverter, More 10 years life.CE standards.

2,CHINT Switch and Button, Best supplier in China.

3, The main motor adopts frequency control of motor speed to improve the speed regulating stability of main motor and save electricity by 30 %. the take-up motor is also adjusted by frequency inverter.

Traction parts: Gusset copied from Taiwan

Gusset copied from Taiwan:

1,Gusset parts is copy from taiwan, easy to adjust.

2, Wooden gusset parts is make

Traction motor:

1, 1.5kw,1400rpm running speed

2, Gearbox: 7.5:1 running speed

3, LG inverter controlling the motor running.Save power and speed adjusting.

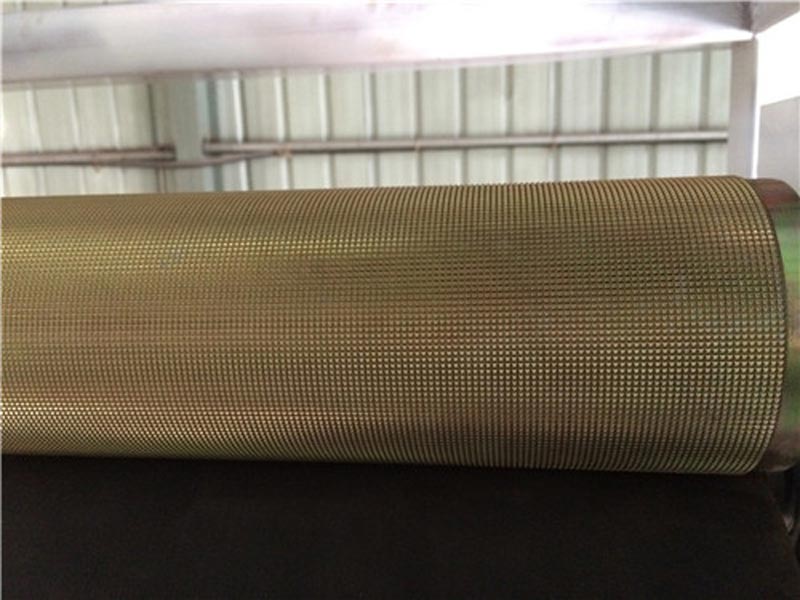

Embossing roller:

1, Dot distance:2mm. We can design it according to yours

2, Controlled by air cylinder, which is easy to operate, no manual working.

Rewinder:

The rewinder adopts pressure friction rewinding or center rewinding device, which is driven by torque motor.

It is even and smooth rewinding and easy roll changing.

Tags:Mini Blown Film Machine,Mini Film Blowing Machine,Mini Blown Film Extrusion,Economic Film Blowing Machine

> What are plastic bags made of?

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produ...

> What is the market prospect of Bag Making Machine?

The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to ma...

> How to Choose a Good Bag Making Machine?

A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and s...

> What are the similarities between fully automatic bag making machines and semi-automatic bag making machines

The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manual...

> What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These mac...

> What is the Manufacturing Process of plastic bag

Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled ...

English

English Français

Français Español

Español