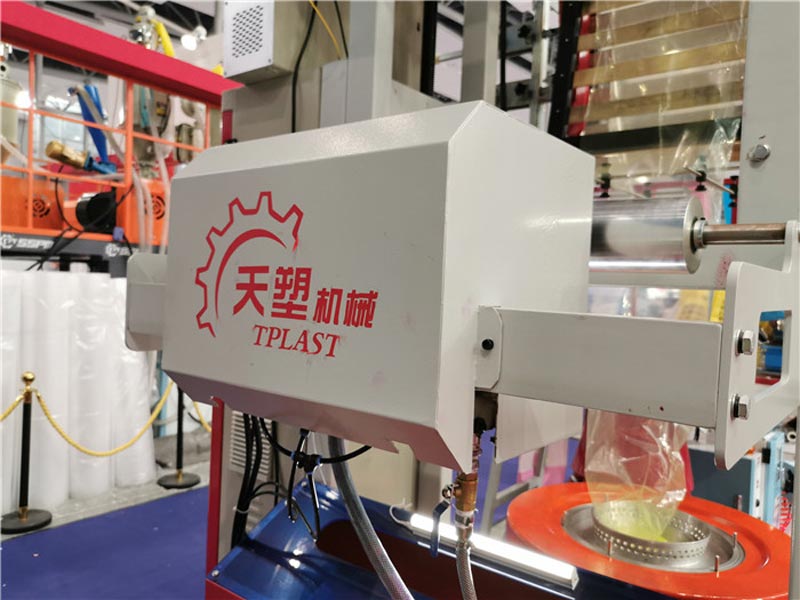

Taiwan Mini Film Blowing Machine With Printing Machine

Mini Film Blowing Machine Features

1. High production efficiency and labor-saving.

2. It has a wide range of bag making and can blow films with a width of 100-500mm.

3. The operation is simple. You can learn to operate the machine on the day you receive the goods. Maintenance is convenient and the cost is low.

4. The thickness of the blown film can be adjusted, of course, this also depends on the tensile properties of the specific vertical raw materials.

5. Excellent material. The extruder, barrel, and screw are all made of high-quality alloy steel and have excellent performance.

6. It can be matched with the corresponding plastic bag-making machine to realize the blown film bag-making process.

Taiwan Mini Film Blowing Machine With Printing Machine is used taiwan design screw and barrel, there are double feeding design, so it can do bigger output. the materials of screw is bimetal, which contain the 15 tunsgen carbine.

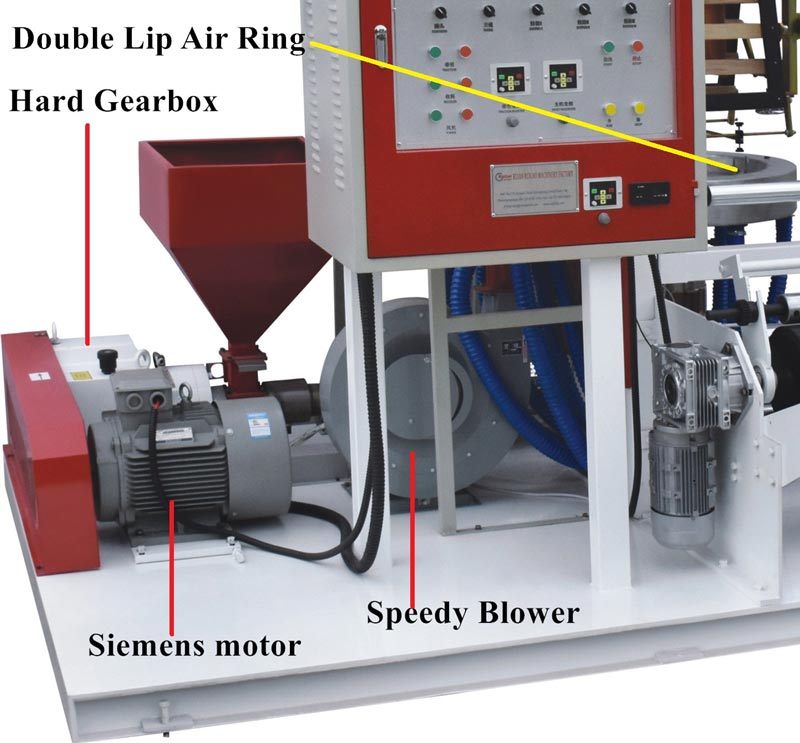

Controlling Box

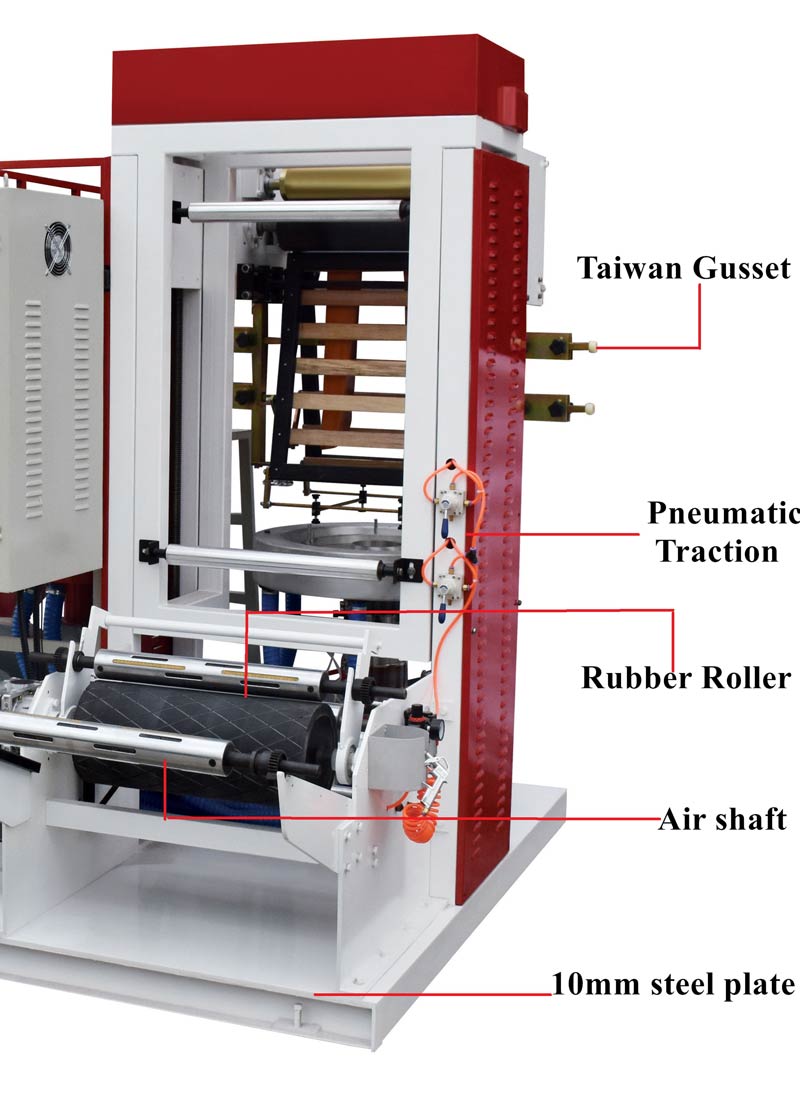

Machine Structure

Main Extruder

What is the Mini Film Blowing Machine used for?

Mini Blown Film Extrusion Machine is a simple film-blowing machine, specially developed for small factories and laboratories. Compared with large film-blowing machines, the Mini Blown Film Extrusion Machine is small in size, saves energy, and occupies a small area. It is widely used in various Packaging bags, such as food bags, shopping bags, vest bags, garbage bags, and other packaging bags.

Mini Film Blowing Machine Parameter:

|

Model |

TPH45 |

|

Diameter of screw |

Φ45 |

|

Max width of Film |

100-500mm |

|

Single-face Thickness of film |

0.008-0.10mm |

|

Output |

55kg/h |

|

L/D |

30:1 |

|

Power of main motor |

11kw |

|

Power of Traction main motor |

1.5kw |

|

Total Power |

25kw |

|

Outline diameter |

4.0*1.5*2.3 |

|

weight |

2500kg |

Mini Film Blowing Machine Main Parts Parameter and pictures:

Electric parts: Omron Temperature controller:

1, Digital show

2, Accurate temperature controlling for 3 centigrade

3, Longer life to more 10 years

4, CHINT brand switch and breaker, best quality in China.

Controller box and LG inverter:

1, LG inveter to adjsut the speed of all motor, which can save the power consumption, protect the motor working.

2, LG inverter is longer time to more 10 years.

3, Easy to adjust the inverter.

4.Taiwan Button

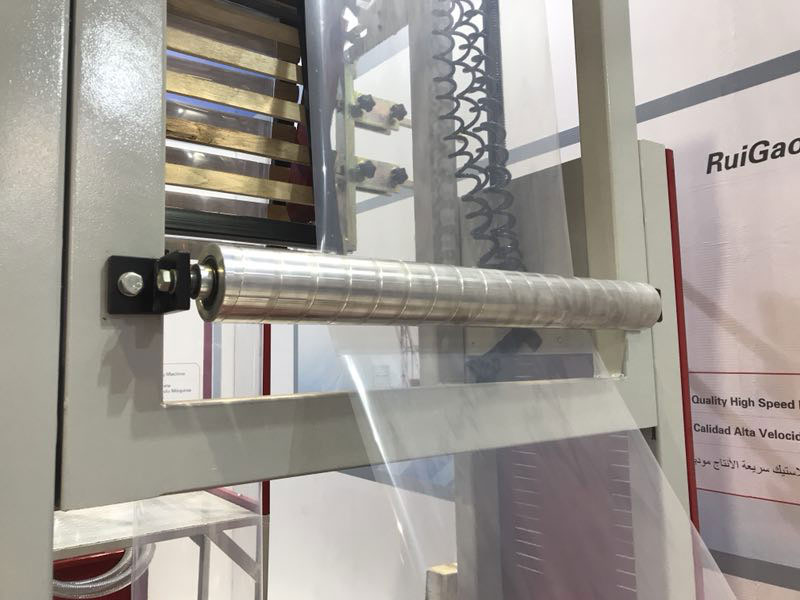

Single Rewinder:

1, Tension control :film will be more tight

2, After roll change ,can fix air shaft automatic ,easy operate

3.Aluminum roller :film will be more even

4, LG inverter controlling motor speed, save power consumption

Main motor: Siemens brand

1, Runing Speed: 1400rpm,

2 Motor power: 380V, 3phase. Pwoer can be changed according yours

3, Motor Life: more 10 years.

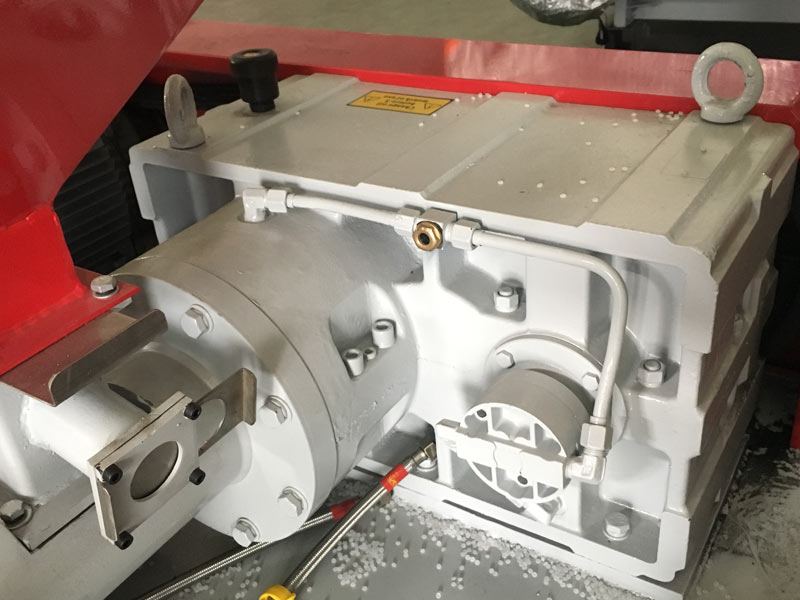

Gearbox:

1, Fucntion: reduce the speed of transferring.

2, Speed rate: 10:1

3, Gear: Hard surface type, high quality.

4, Lubrication oil for transfering

5, Low noise and longer life

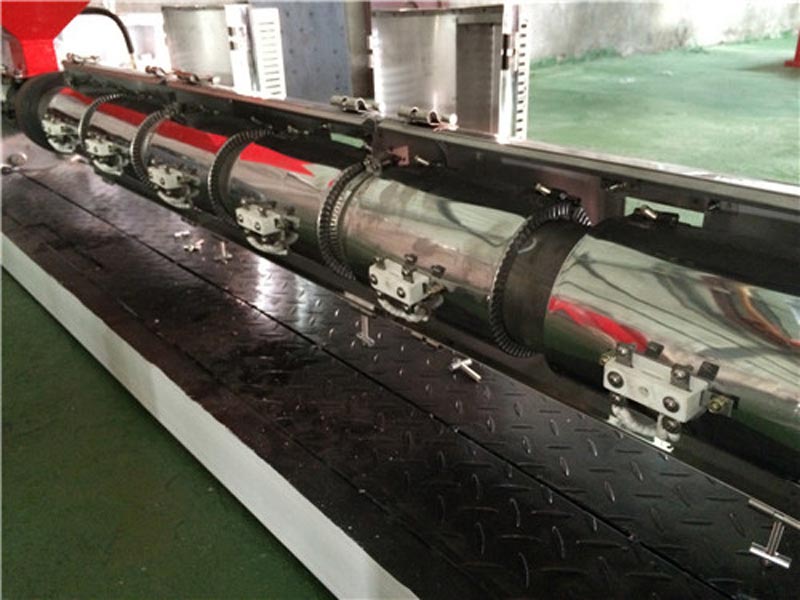

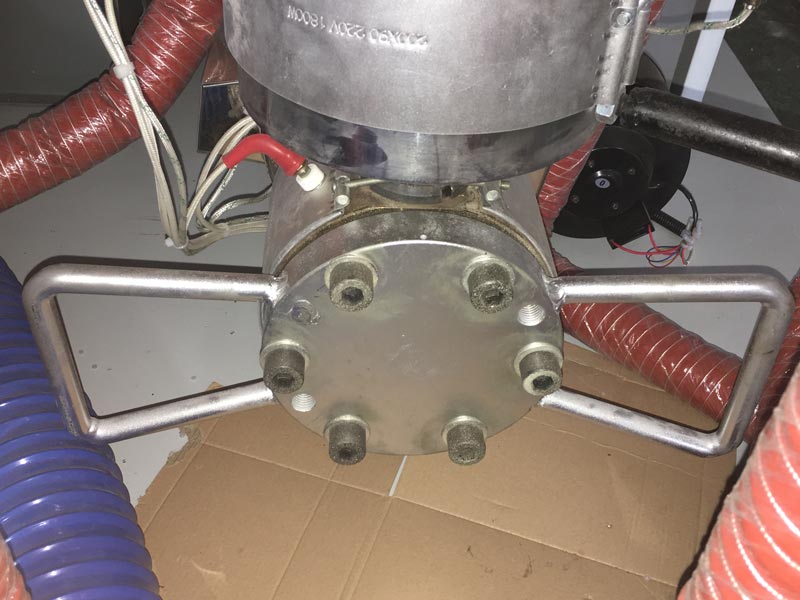

Heater: Ceramic heater fucntion:

1, Heating faster than stainless heater.

2, Life is longer to 5 years.

3, Keeping hot inside is longer than stainless, save power.

4, High quality ceramic and heating wire Inside.

Aluminum roller instead of banana roller

Taiwan newest technical

Film will be more even

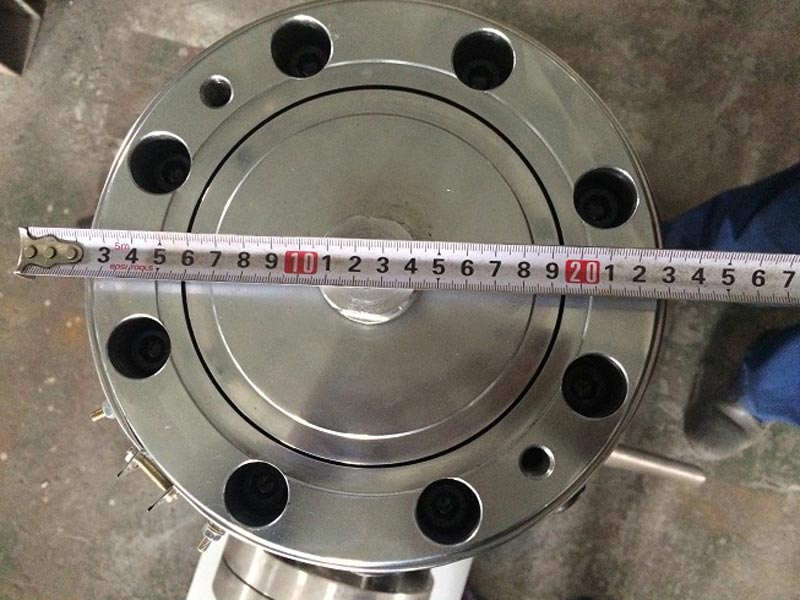

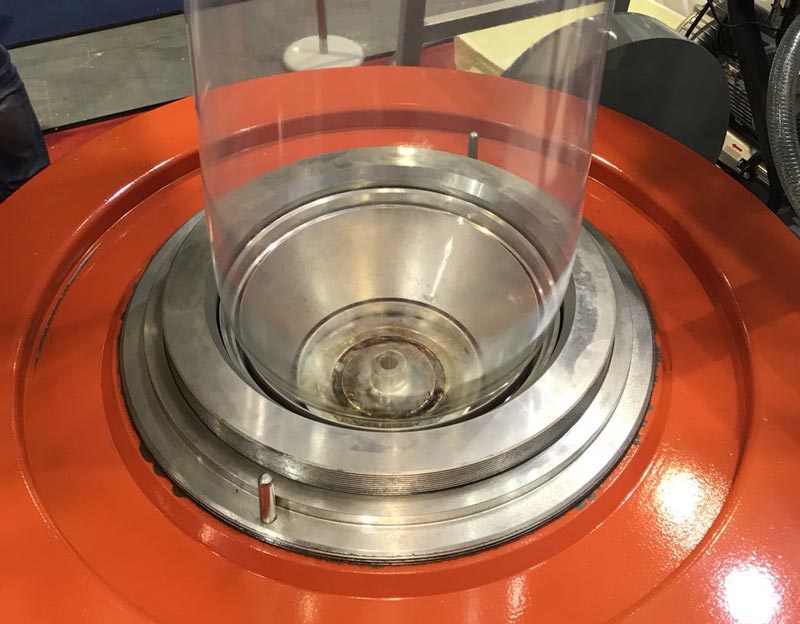

High Speed Die head: Taiwan design high speed die head:

1, #45 steel stronger

2, Surface treatment,which make film more transparent

3,bigger size than normal, which improve the output of machines

Fixed Die head: Taiwan design high speeddie head:

1, #45 steel stronger

2, Surface treatment,which make film more transparent

3, bigger size than normal, which improve the output of machines

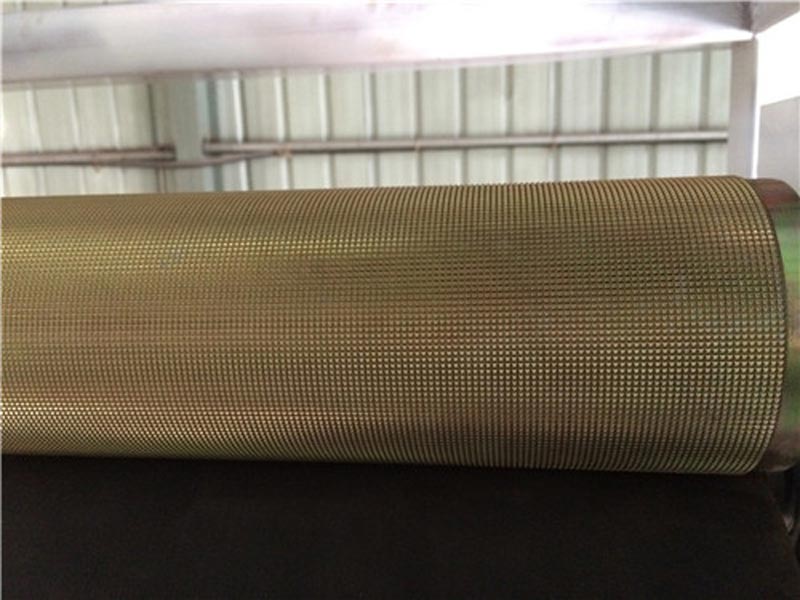

Embossing roller:

1, Dot distance:2mm. We can design it according to yours.

2, Controlled by air cylinder, which is easy to operate, no manual working.

Screen change: T Type

Screw: Copied from Taiwan, Bimetal with Tungsten Carbide

1.Material of screw and barrel: 38CrMoAlA

2.Material Element Analysis:

C: 0.35~0.42 Si: 0.20~0.45 Mn: 0.30~0.60 S: ≤0.035 P: ≤0.035

Cr:1.35~1.65 Al: 0.70~1.10 Ni: ≤0.030 Cu: ≤0.030 Mo:0.15~0.25

3.Hardness of tempering: HB260-290

4.Depth of nitriding: 0.4-0.7mm

5.Hardness of surface: HV900-1050

6.Roughnessof surface:Ra0.32

7.Linearity of screw: 0.015mm/m

8.Bimetal screw: Bimetal layer on the screw thread

9.Hardness of bimetal layer: HRC58-62

10. Depth of bimetal layer: 2-3mm

11. Bimetal layer elements: Fe, Ni, Wc, B, C, Cu, ect

Taiwan Double Lip Air ring:

1, Taiwan quality two lip Air ring to cool the film, it is faster than one lip.so it can improve the output of machine

2, it special do HDPE.

Traction parts: Gusset copied from Taiwan

Gusset copied from Taiwan

1, Gusset parts is copy from taiwan, easy to adjust.

2, Wooden gusset parts is make.

3, gusset wooden with angle ,not flat.

Printing Part:

1, it is single color. Printing length 500mm

2, Just need air, No power consumption,

3, No need worker to operate printing machine

Whole machine: Nice design

Mini Film Blowing Machine Price

Tplast provides various types of small film-blowing machines. Tplast Mini Film Blowing Machine Manufacturer tells you that the price of the film blowing machine is related to the model and other supporting equipment, transportation area, purchase quantity, etc. We provide various types of Film Blowing Machine to Meet the production needs of different manufacturers. If you want to know more about the price of the mini film-blowing machine, please leave us a message.

Tags:Mini Film Blowing Machine Manufacturer,Mini Blown Film Extrusion Machine,Small Film Blowing Machine,Mini Film Blowing Machine for Plastic,Mini Film Blowing Machine Price,HDPE Film Extruder Machine,Taiwan Film Blowing Machine

> What are plastic bags made of?

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produ...

> What is the market prospect of Bag Making Machine?

The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to ma...

> How to Choose a Good Bag Making Machine?

A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and s...

> What are the similarities between fully automatic bag making machines and semi-automatic bag making machines

The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manual...

> What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These mac...

> What is the Manufacturing Process of plastic bag

Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled ...

English

English Français

Français Español

Español