3 Layer Film Blowing Machine With Ibc And Haul Off

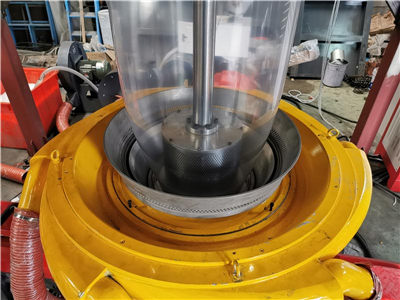

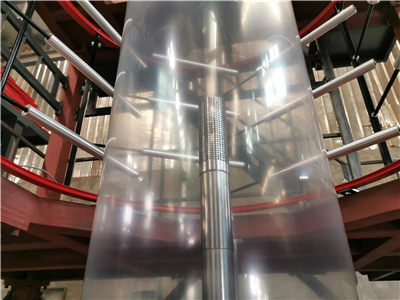

3 Layer Film Blowing Machine With Ibc And Haul Off is design the rotary tower which will slove the thickness problems. And there is Inner cooling system, which can control the temperature of film and inner temperature.

3 Layer Film Blowing Machine With Ibc And Haul Off Characteristics:

1. IBC control: IBC (internally blown film container) control is an important feature of the three-layer blown film machine. It allows precise control of film thickness and uniformity during film production. The IBC control system can monitor the thickness of the film in real-time and make adjustments as needed to ensure that the thickness of the film meets the preset requirements.

2. Raul-type spiral mandrel: The die head adopts Raul type of spiral mandrel, which can improve the stability during the film-blowing process and reduce the fluctuation of the film bubble, thereby ensuring that the thickness and quality of the film are more uniform.

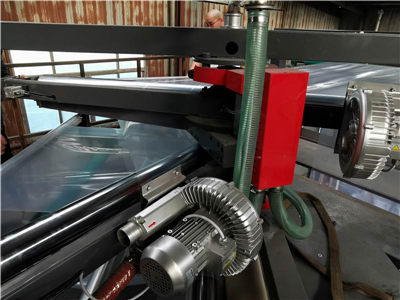

3. Quick filter replacement device: This equipment is reasonably designed, convenient, reliable, and safe to operate. This means the filter replacement process can be carried out quickly and efficiently, reducing downtime and increasing production efficiency.

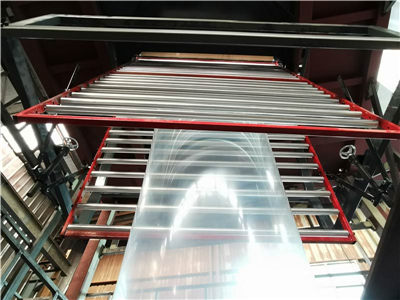

4. Various functional components can be installed: The three-layer film-blowing machine can be equipped with various functional components, such as a length counting device, slitting device, cooling water drainage pipe, film laying roller, waste collection device, etc. These additional parts can be selected according to production needs to meet different production requirements.

5.Top rotary tower design: The top rotary tower design of the three-layer film-blowing machine can improve the automation and reliability of the equipment. The turret can be moved and rotated during the production process to facilitate maintenance and inspection of the film head and extruder head. This design also provides better observation and operating conditions, allowing operators to monitor the production process more intuitively.

In general, the three-layer film-blowing machine with IBC and traction functions has the characteristics of high efficiency, stability, flexibility, and easy maintenance, and can meet the film production needs of different industries.

3 Layer Film Blowing Machine Main Technical Variables:

|

Model |

SJ-50*3/TP1000 |

SJ-55*3/TP1200 |

SJ-60*3/TP1500 |

SJ-70*3/TP2000 |

|

Screw Diameter(mm) |

45/50/45 |

50 /55/50 |

55/65/55 |

65 /75/65 |

|

Screw Ratio(L/D) |

30:1 |

30:1 |

30:1 |

30:1 |

|

Screw Speed(r/min) |

110 |

110 |

110 |

110 |

|

Power of Main Motor(kw) |

11/15/11 |

15/18.5/15 |

18.5/22/18.5 |

30/45/30 |

|

Range of Die(mm) |

¢200 |

¢300 |

¢350 |

¢500 |

|

single-sided Thickness of Film(mm) |

0.025-0.15 |

0.025-0.15 |

0.03-0.15 |

0.03-0.20 |

|

Max.Folding Width of Film(mm) |

1000 |

1200 |

1500 |

2000 |

|

Max output |

150kg/h |

160kg/h |

180kg/h |

230kg/h |

|

Electric Total Capacity(kw) |

95 |

100 |

120 |

180 |

|

Weight of Machine(kg) |

7500 |

8000 |

9000 |

10500 |

|

Overall Dimensions (L*W*H)(m) |

6.6*2.8*8 |

6.8*3*8.5 |

7*3.2*10 |

8.5*5*10.5 |

3 Layer Film Blowing Machine Picture

The three-layer blown film extruder production line can produce LDPE, HDPE, LLDPE, MLLPE packaging films with a thickness of 0.025-0.15mm. These films have good solubility and can be used for various light and heavy packaging, such as fresh fruits, Meat, pickles, fresh milk, drinks, etc. These films have advantages such as thermal insulation, moisture-proof, windproof, rainproof, rust-proof, heat-insulating oxygen, oil resistance, etc., and can meet the packaging needs of different products. At the same time, the production line is efficient, stable, flexible, and easy to maintain, and can meet the production needs of different industries.

> What are plastic bags made of?

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produ...

> What is the market prospect of Bag Making Machine?

The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to ma...

> How to Choose a Good Bag Making Machine?

A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and s...

> What are the similarities between fully automatic bag making machines and semi-automatic bag making machines

The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manual...

> What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These mac...

> What is the Manufacturing Process of plastic bag

Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled ...

English

English Français

Français Español

Español