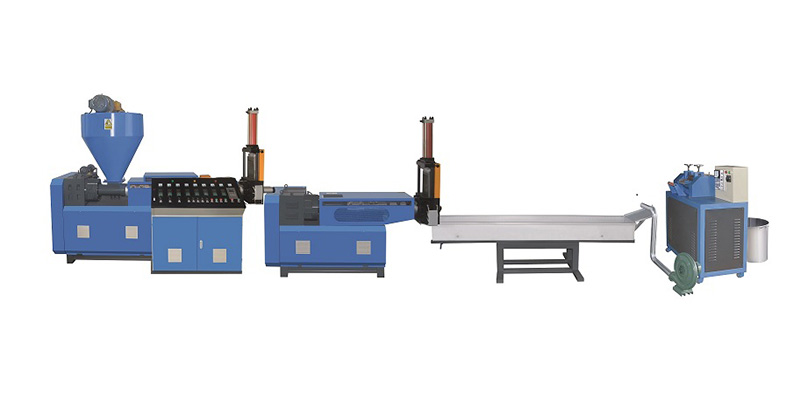

Plastic Recycling Machine Two Stage

SJ-90、100、110、120C Waste Plastics Recycling Machine is used for recycling of the used and waste plastic materials. It is equipped with automatic constant temperature, electric changing filter nets. It also can pelletize the crushing material after fitting with a loader. The cutting machine adopts speed regulating motor, which can cut the material according to the feeding speed of the extruder. With such features as high output, low noise, stable performance and easy operation. It is a more ideal waste plastic film regenerative pelletizer.

Main Technical Variables:

|

Model |

SJ-90C |

SJ-100C |

SJ-110C |

SJ-120C |

SJ-140C |

|||||

|

Diameter of Screw Stem |

90/100mm |

100/100mm |

110/110mm |

120/110mm |

140/130mm |

|||||

|

L:D |

20:1/12:1 |

20:1/12:1 |

20:1/12:1 |

20:1/12:1 |

20:1/12:1 |

|||||

|

Speed of Screw |

10-110rpm |

10-110rpm |

10-110rpm |

10-110rpm |

10-110rpm |

|||||

|

Gearbox |

180/173 |

180/173 |

180/173 |

200/173 |

225/180 |

|||||

|

Motor Power |

22kw/15KW |

22kw/15KW |

37kw/15KW |

37kw/18.5KW |

55kw/22KW |

|||||

|

Output |

110kg/h |

130kg/h |

150kg/h |

180kg/h |

220kg/h |

|||||

|

Water Tank Length) |

2800mm Stainless

|

|||||||||

|

Screen changer |

Hydraulic for both screw |

|||||||||

|

Screen changer hole |

6mm |

|||||||||

|

Die head hole(Alloy Metal) |

4mm |

|||||||||

|

Cutter Knife |

Hobbing Cutter(Alloy Steel) |

|||||||||

|

Cutter Motor |

2.2kw |

2.2kw |

3kw |

3kw |

3kw |

|||||

|

Machine Weight |

2.4t |

2.6t |

2.8t |

3t |

4t |

|||||

|

Overail Dimensions |

8.8*1.5*1.1m |

9*1.3*1.2m |

9.2*1.3*1.3m |

9.6*1.4*1.3m |

9.6*1.5*1.3m |

|||||

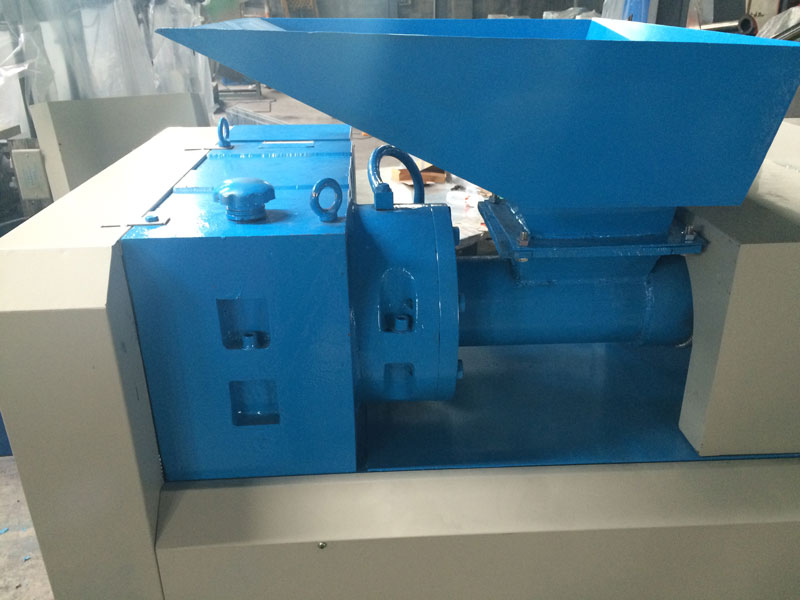

1, Machine Details: Gearbox and Loader

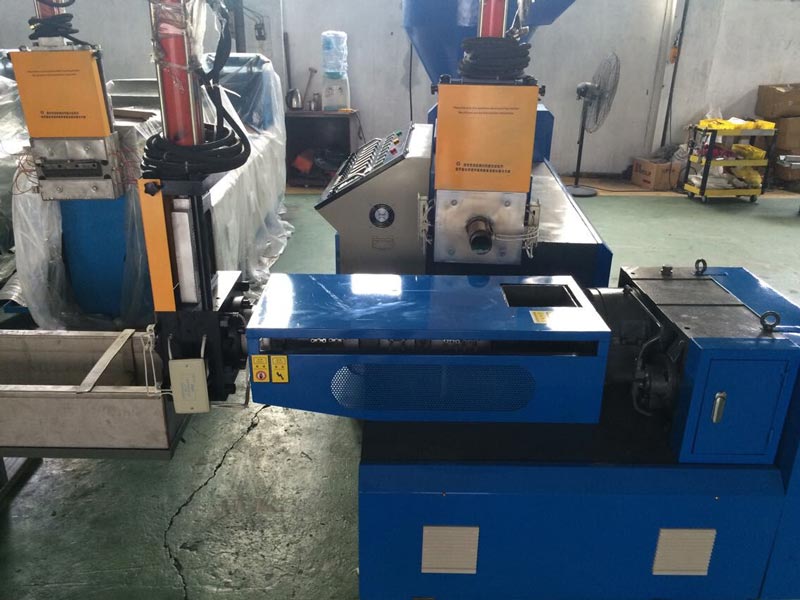

2, Machine Details: Die head and Hydraulic Screen Changer

3, Main Extruder

4, Dry blower:high speed type, 0.75kw.

5, Machine Details: Wire connection and Electric Box, there are two inverter to control two main motor. Other is just one inverter.

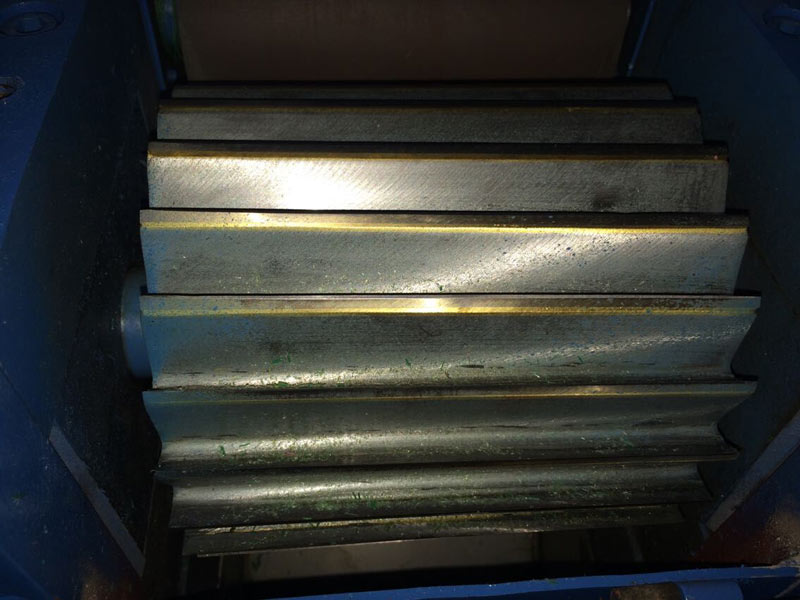

6, Hobbing Cutting knife(Alloy materials) and Final Product

> What are plastic bags made of?

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produ...

> What is the market prospect of Bag Making Machine?

The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to ma...

> How to Choose a Good Bag Making Machine?

A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and s...

> What are the similarities between fully automatic bag making machines and semi-automatic bag making machines

The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manual...

> What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These mac...

> What is the Manufacturing Process of plastic bag

Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled ...

English

English Français

Français Español

Español