High Speed 6 Color Printing Machine

High Speed 6 Color Printing Machine is a printing machine that uses a photosensitive resin soft plate as a printing plate material, usually called a "flexo printing machine." Suitable for printing polyethylene, polypropylene plastic bags, cellophane, roll paper and other packaging materials. It is an ideal printing equipment for food paper packaging, supermarket handbags, vest bags, clothing bags, etc.

Technical Data:

|

Model of Machine |

YT-6600 |

YT-6800 |

YT-61000 |

YT-61200 |

|||||

|

Max.Width of Printing Material |

600mm |

800mm |

1000mm |

1200mm |

|||||

|

Max.Printing Width |

560mm |

760mm |

960mm |

1160mm |

|||||

|

Length Range of Printed Product |

191-1200mm |

191-1200mm |

191-1200mm |

191-1200mm |

|||||

|

Max.Diameter of Roll Material |

φ450mm |

φ450mm |

φ450mm |

φ450mm |

|||||

|

Printing Speed |

70m/min |

70m/min |

70m/min |

70m/min |

|||||

|

Accuracy of Registration |

±0.25mm |

±0.25mm |

±0.25mm |

±0.25mm |

|||||

|

Thickness of plate(Including Two-sides Glue Paper) |

2.38mm |

2.38mm |

2.38mm |

2.38mm |

|||||

|

Total Power |

10kw |

10kw |

11kw |

11kw |

|||||

|

Weight of Machine |

3500kg |

4200kg |

5000kg |

5500kg |

|||||

|

Overall Dimensions(mm) |

5500×1660×2950 |

5500×1860×2950 |

5500×2060×2950 |

5500×2260×2950 |

|||||

Standard Unwinder& Rewinder Part:

|

1,Double Unwinder & Rewinder: easily to change rolls and save time

|

||

| 2, Automatic tension Brake 5kg | ||

|

|

||

| 3, Tension sensor | ||

|

||

|

|

4, Auto Tension Controller

|

|

|

|

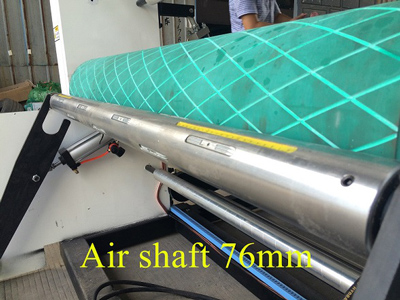

5, Air shaft: |

|

|

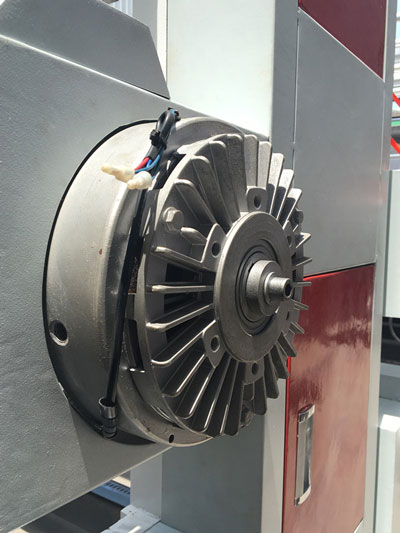

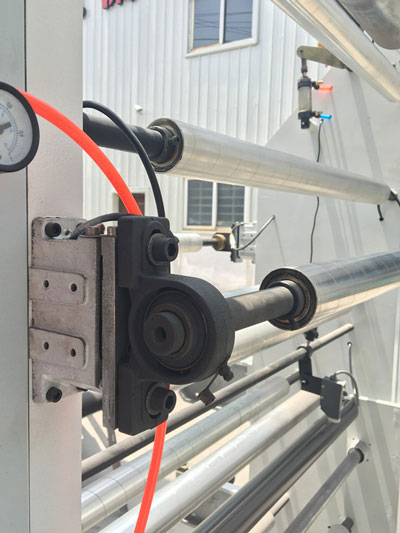

6, EPC Motor |

|

|

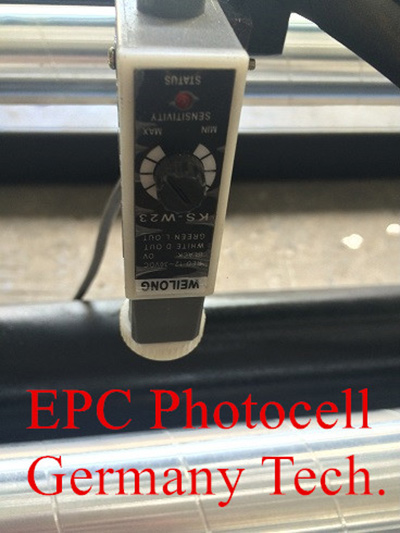

7, EPC Sensor |

|

Printing Part:

|

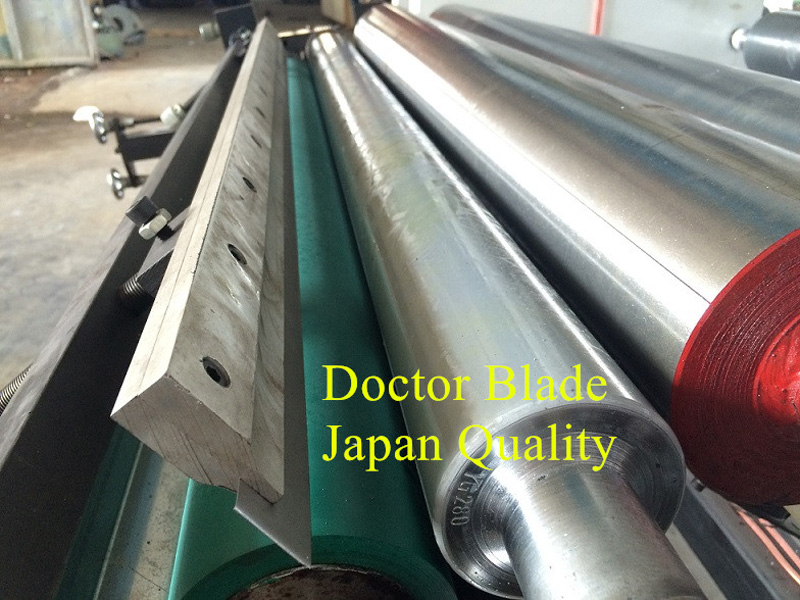

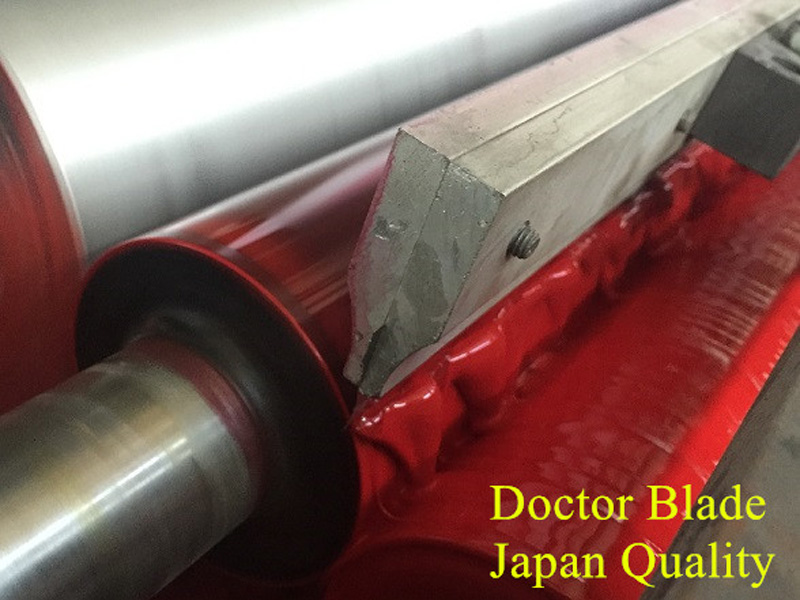

1, Doctor Blade: We use Metal Blade which can make the ink more even on anilox roller.

|

|

|

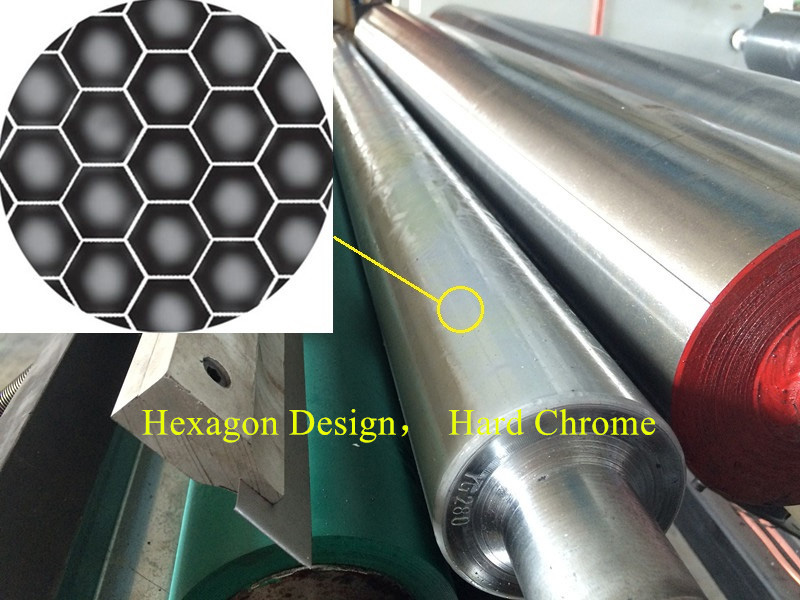

2, Anilox Roller: Steel anilox roller can do Max 320LPI, and Hexagon Design, so it can put max ink in dot. Anilox roller is designed by printing pictures.

|

|

|

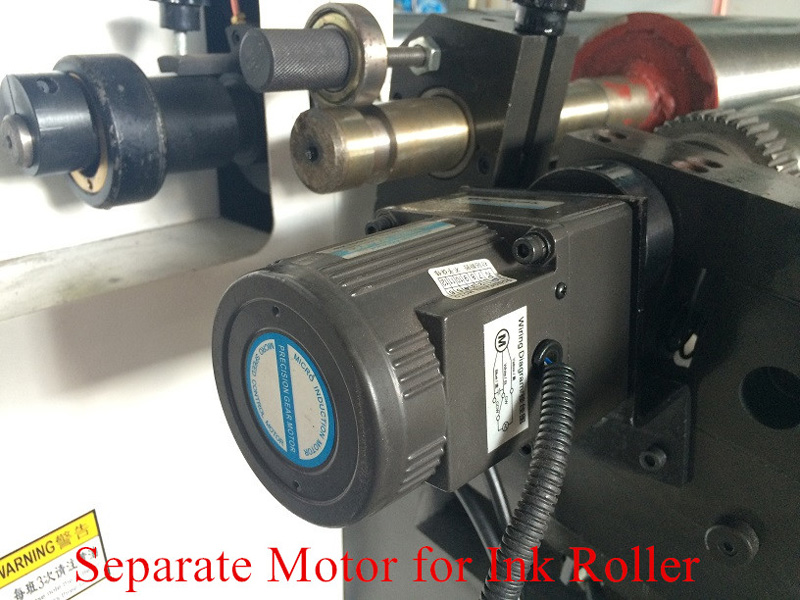

3,Separate Motor for Ink Roller. It will automatic running when machine is stop, and it can keep the ink running. No dry for ink

|

|

|

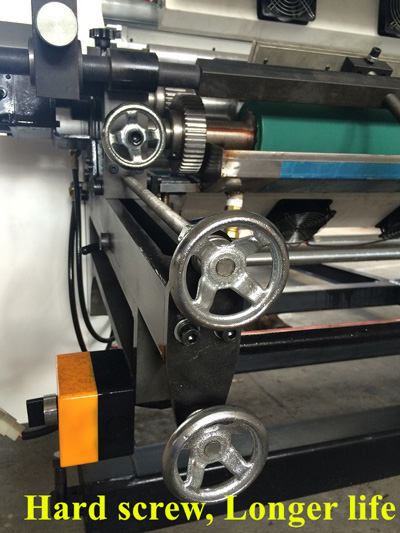

4, Adjust Bar: Stronger steel as bar.

|

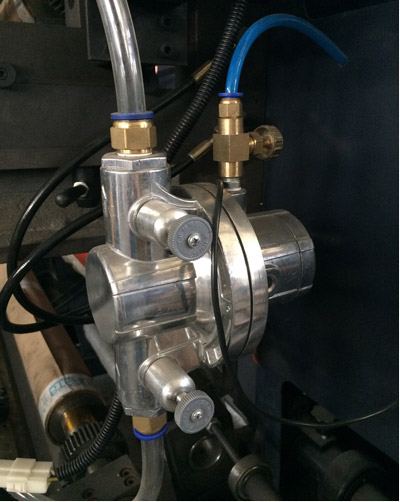

5, Ink pump : No need worker to add ink

|

|

6, Oil Lubrication System, it can make machine running

|

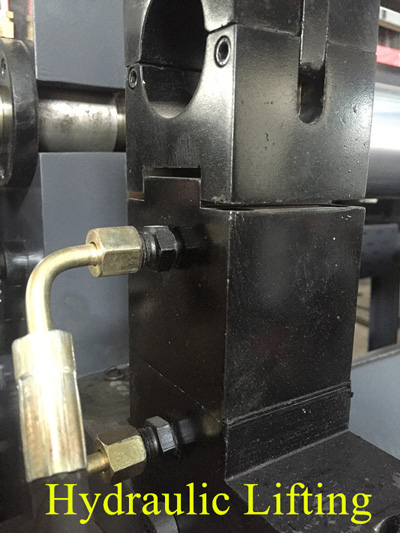

7, Hydraulic Lifting System, which is more stable than pneumatic,

|

Transfering parts:

|

|

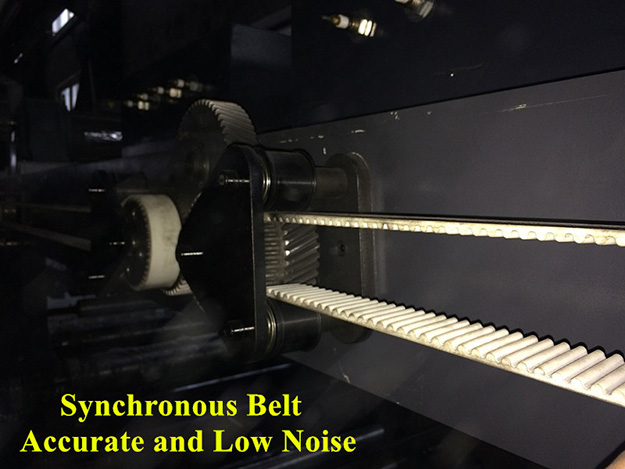

1,Synchronous Belt It make the printing precision |

|

|

2, Helical Gear Very hard. It is with high precision |

|

|

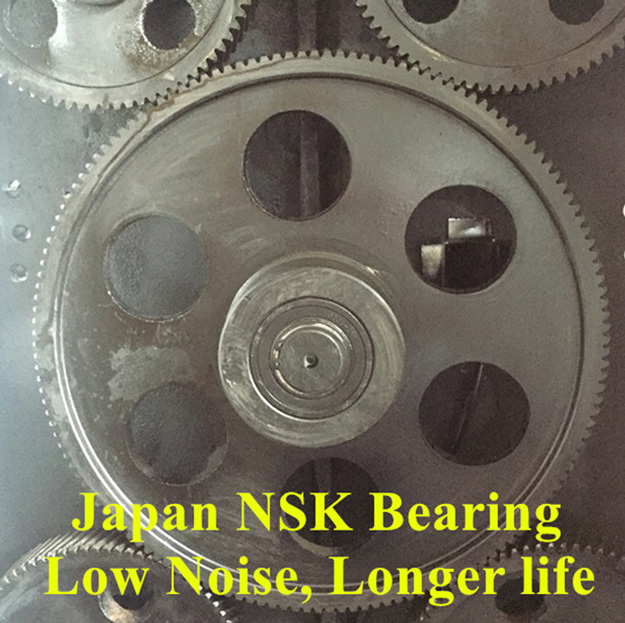

3, NSK Bearing Best Brand in Japan, |

Drying Parts:

|

|

1, Separate Heating drying |

|

2, Up Drying System, with hot and cold drying parts. So whole machine can run 70m/min and the printing ink can dry with good condition.

|

|

> What are plastic bags made of?

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produ...

> What is the market prospect of Bag Making Machine?

The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to ma...

> How to Choose a Good Bag Making Machine?

A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and s...

> What are the similarities between fully automatic bag making machines and semi-automatic bag making machines

The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manual...

> What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These mac...

> What is the Manufacturing Process of plastic bag

Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled ...

English

English Français

Français Español

Español