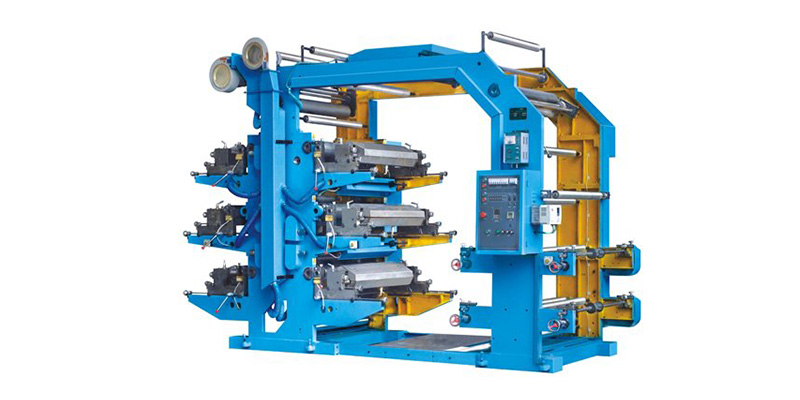

Normal 6 Color Printing Machine

Technical Data:

| Type | YT-6600 | YT-6800 | YT-61000 | YT-61200 |

| Max.Effective Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max.Web Width | 600mm | 800mm | 1000mm | 1200mm |

| Max.Printing Speed | 50m/min | 50m/min | 50m/min | 50m/min |

| Max.Mechanical Speed | 60 m/min | 60 m/min | 60 m/min | 60 m/min |

| Max. Diameter of Roll Material | ф450mm | ф450mm | ф450mm | ф450mm |

| Internal Diameter of Roll Core | ф76mm | ф76mm | ф76mm | ф76mm |

| Rang of Repeat Printing Length | 191-1200mm | 191-1200mm | 191-1200mm | 191-1200mm |

| Accuracy of Registration | ±0.25mm | ±0.25mm | ±0.25mm | ±0.25mm |

| Plate Thickness(Both side adhesive included) | 2.38mm | 2.38mm | 2.38mm | 2.38mm |

| Heating Power | 8Kw | 9Kw | 10Kw | 12Kw |

| Total Power | 11.5Kw | 15Kw | 18.5Kw | 22Kw |

| Weight of Machine | 3500kg | 3500kg | 4000kg | 4500kg |

| Overall Dimension | L4300×W1700×H2500mm | L4300×W1900×H2500mm | L4300×W2100×H2500mm | L4300×W2300×H2500mm |

Main Parts---Unwinder

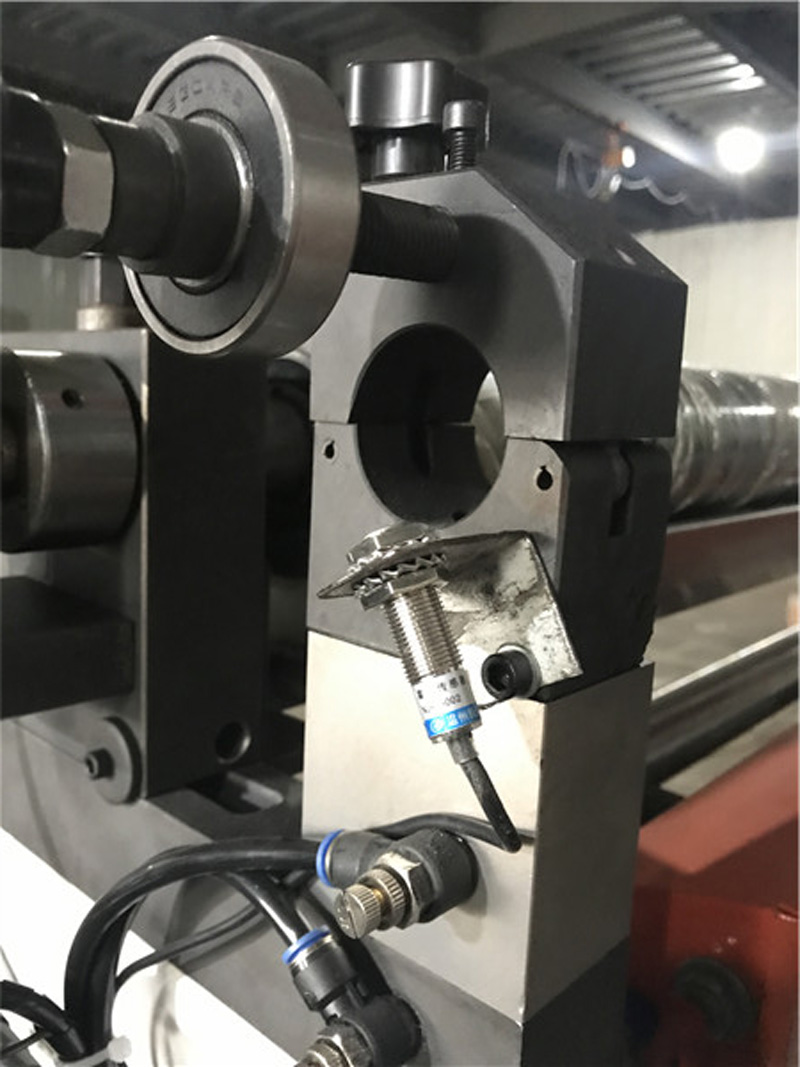

1, Automatic tension cotnrol with 2.5kg magnetic brake. Reduce workers’ mistake

2, Motor type EPC, which can make film edge at same lines

|

|

|

|

|

3, Air shaft, which can improve working efficency

4, Automatic stop Machine when material is running out

Main Parts---Rewinder

1, Automatic tension Control and Air shaft

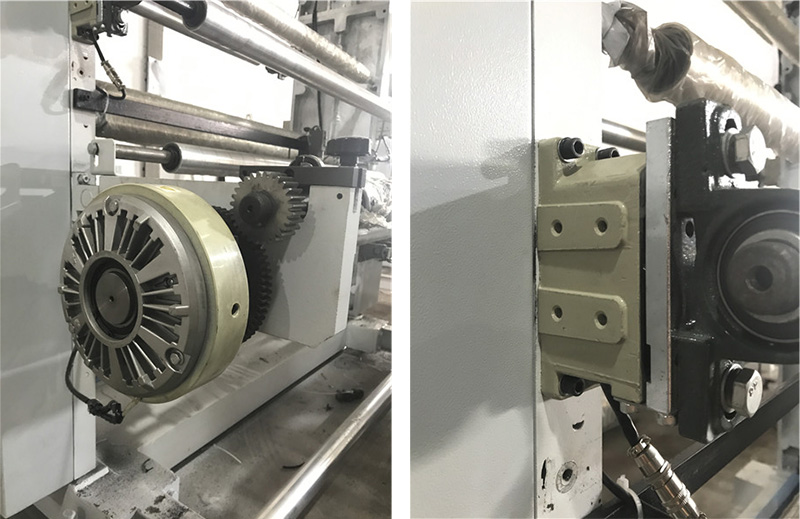

Main Parts--- Machine Driving System

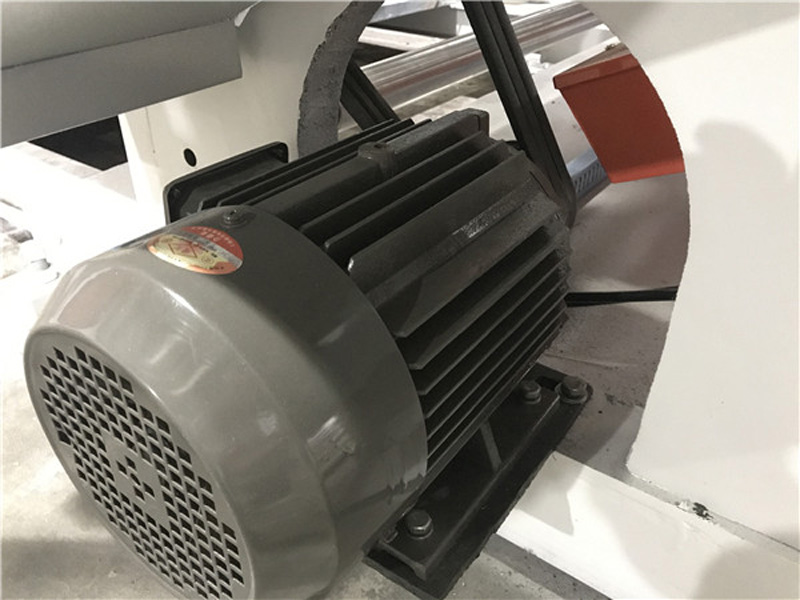

1, Main Motor: CE standards, which is for more 10 years life

2, Each color Driving by gear, which is longer life, but we need put lubrication oil on gear. It will be more smoothly and low noise.

3, Whole Printing Driving System. It is straight Gear for hole machines. We need put Lubrication oil.

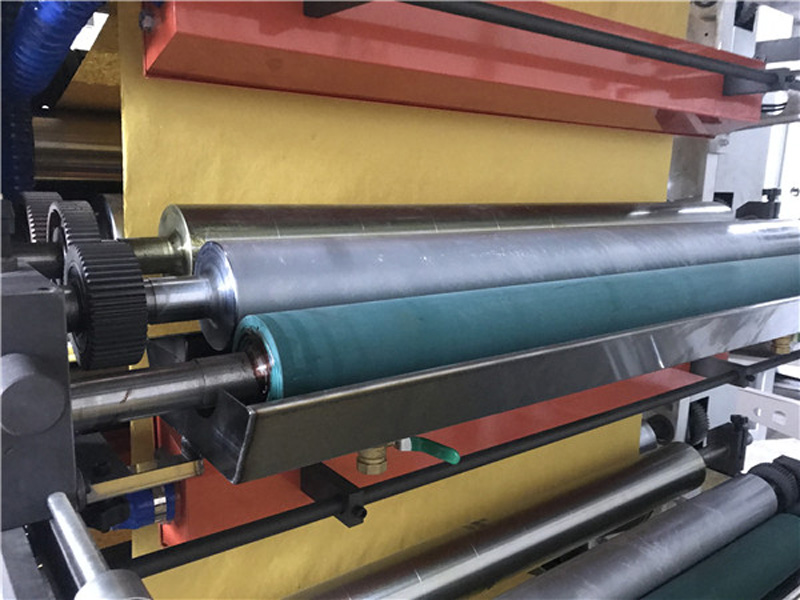

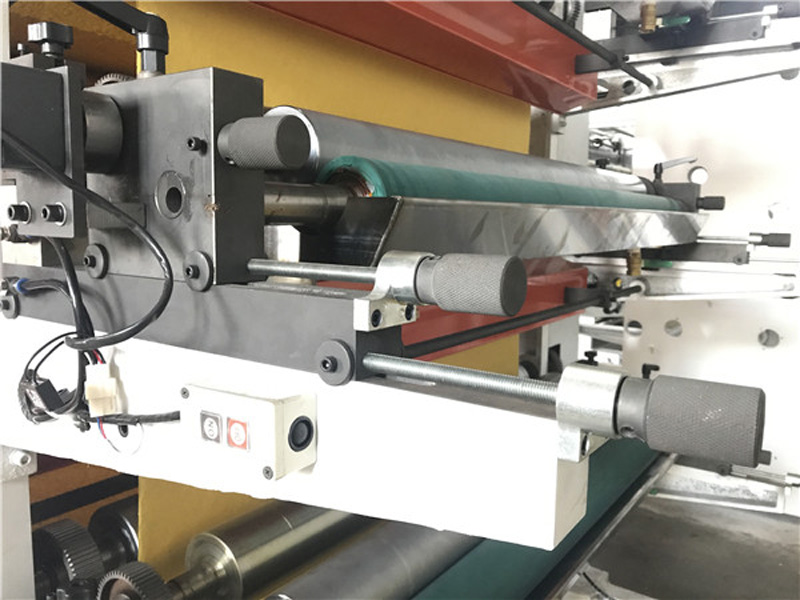

Main Parts--- Printing System

1, High Quality Ink rubber roller, no corrosion from ink

2, Stronger Adjust bar

3, Separate Ink Motor, which can run the ink roller when machine is stop. So the ink cannot dry easily

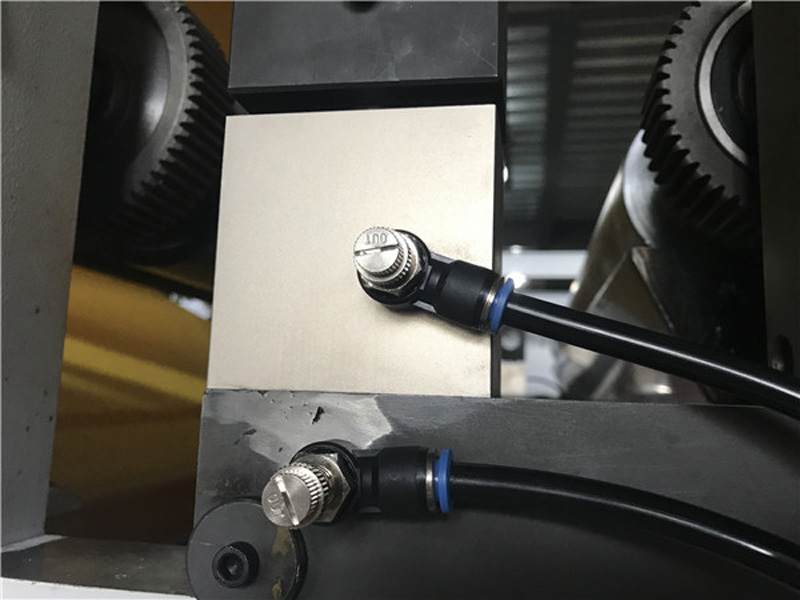

4, Air Lifting System for Plate roller, it is easily to operate

5, Printing Color Match Adjusting parts

6, Counting meter to calculate printing length

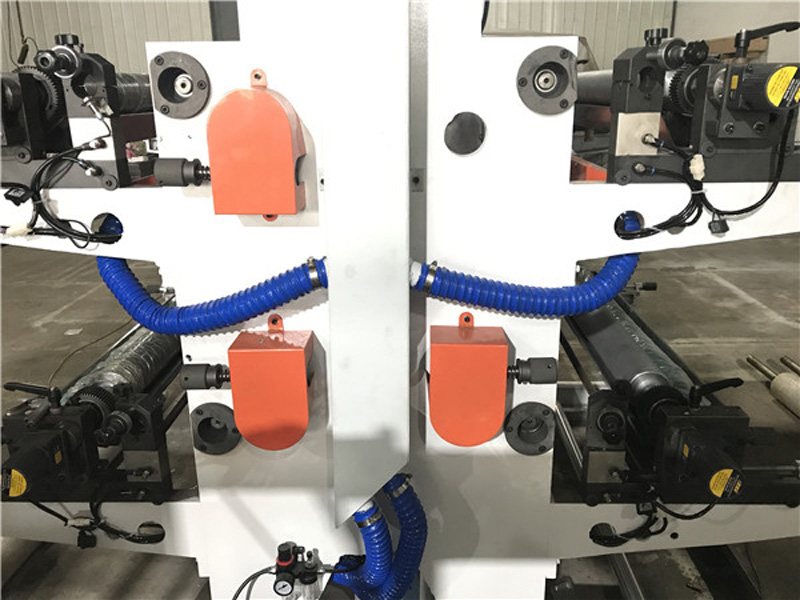

Main Parts--- Dry System

1, There is big Oven on top of machine, which can dry the printing pictures

2, Separate Oven For Each color, so it can dry ink faster

Main Parts--- Electric Parts

1, Delta Inverter and Automatic tension

Whole Machine

> What are plastic bags made of?

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produ...

> What is the market prospect of Bag Making Machine?

The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to ma...

> How to Choose a Good Bag Making Machine?

A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and s...

> What are the similarities between fully automatic bag making machines and semi-automatic bag making machines

The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manual...

> What is Patch Bag Making Machine and Its core functions?

A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These mac...

> What is the Manufacturing Process of plastic bag

Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled ...

English

English Français

Français Español

Español