English

English

English

English

First we put the film roll on the unwinder of bag making machine. The Unwinder motor is controlled by Delta inverter. So it can protect the motor better. The AC unwinder motor will pull the film roll, the speed will be same to the main machine speed.

After that, there is Panasonic photocell, which is for tracking printing bag. Then there is heating knife to seal the bag. Our Sealing knife have two sealing lines, which is very stronger than single lines.

After that, there is cutting knife, which will cut the flat bag and shopping bag both.

The cutting bag length is controlled by Servo motor, which is very accurate and high quality. And the main motor is Taiwan brand, it is containing the brake system. The main motor is controlled by Delta brand inverter.

Each year we improve our machine quality. We will follow our customer feedback and our industry advanced company technology. We will not stop the quality improvement.

After sale service is important for our customer. It is for whole life of machines. If customer feedback any problems we will help him to slove it and rethink our machine design.

We have very professional research and sale team. We will try our best to improve their income and happiness both. Beacuse if they feel happy, our customer will be happy also.

Tplast is china bag making machine factory,provides an operation video, price list, and cost analysis, summarizes and organizes the characteristics of bag making machine, common problems and treatment methods, debugging methods, and other knowledge to let you understand and better operate this machine.

The main materials of plastic bags are polymers, the most common of which is polyethylene (PE). Polyethylene is derived from ethylene, a hydrocarbon gas. It is produced through a polymerization process in which multiple ethylene monomers are chemically bonded together to form long chains.

Read More >The market prospect of Bag Making Machine is broad. Under various factors, the market will continue to grow and develop. Enterprises also need to pay attention to market changes and technological trends

Read More >A good bag making machine is versatile, producing various bag types and sizes with customizable features. It offers high-quality output through precise cutting and sealing and consistent results. Oper

Read More >The fully automatic cold cutting bag making machine can directly produce vest bags, while the semi-automatic cold cutting bag making machine requires labor to manually press vest bag.

Read More >A patch bag-making machine is a specific type of equipment used in the production of patch handle bags, which are commonly used for shopping and packaging. These machines are designed to efficiently m

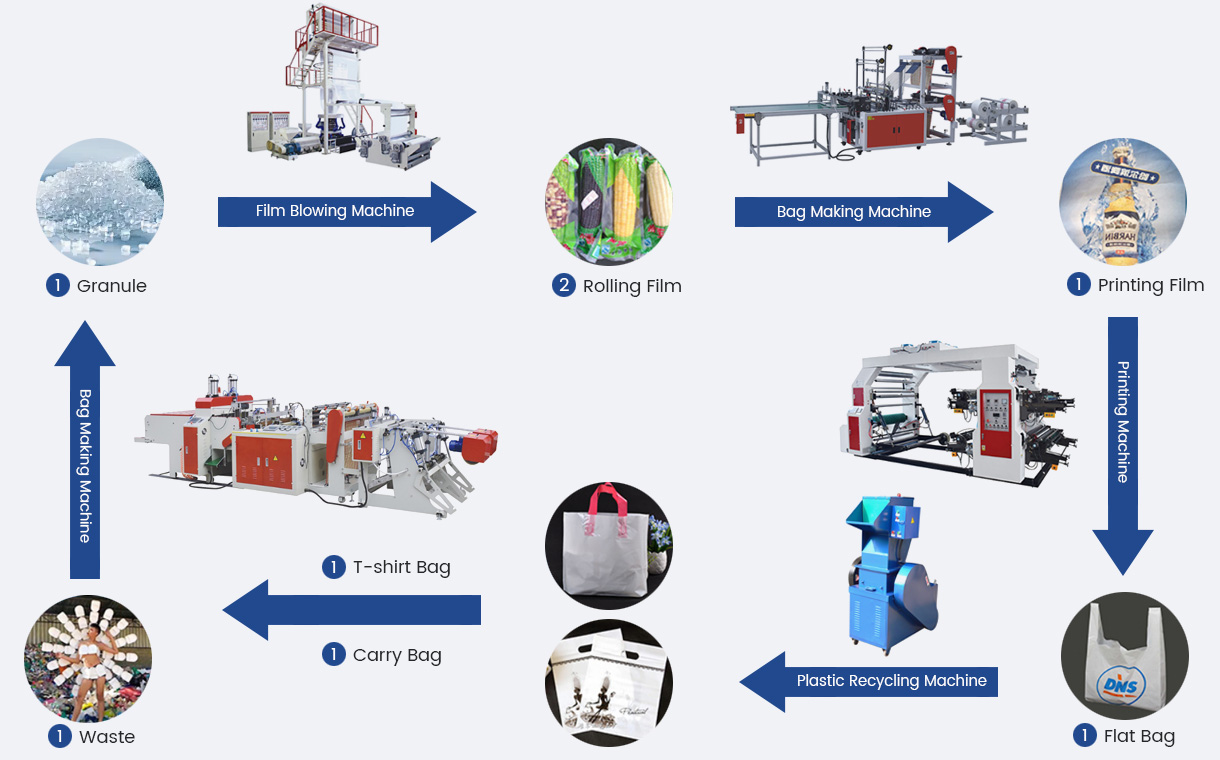

Read More >Plastic bags, an everyday convenience in modern life, are produced through a well-defined manufacturing process that combines raw materials, technology, and skilled labor. From the initial stages of r

Read More >GET A QUOTE